In today's competitive manufacturing landscape, CNC precision machining has become a cornerstone for industries demanding high accuracy and repeatability. As a leading CNC Machining factory, EMAR specializes in delivering tailored solutions that meet stringent quality standards while optimizing production workflows.

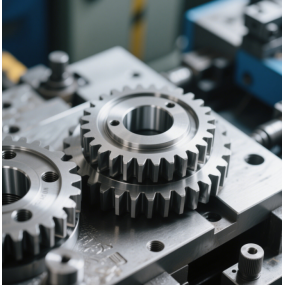

The Core Advantages of CNC Precision Machining

Modern CNC technology enables micron-level tolerances, complex geometries, and consistent output – critical for aerospace, automotive, and medical applications. Our CNC machining services leverage advanced 5-axis systems and rigorous quality control protocols to ensure dimensional perfection across prototypes and mass production.

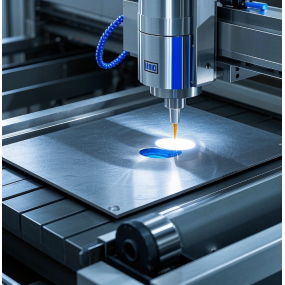

EMAR's Technical Differentiation

With ISO 9001-certified facilities in China, we combine cutting-edge equipment (Mazak, DMG Mori) with DFM expertise to reduce clients' per-unit costs by 15-30%. Our engineers excel in machining exotic alloys, plastics, and composites with specialized tooling solutions.

Streamlined Production Workflow

From CAD/CAM programming to final inspection, EMAR implements digital twin technology for error-free manufacturing. Real-time monitoring systems guarantee 99.8% on-time delivery, while our material traceability system meets AS910 requirements for regulated industries.

Why Global Clients Choose EMAR

500+ manufacturers trust our turnkey capabilities including secondary processing (anodizing, plating) and assembly services. Case studies demonstrate 40% faster lead times compared to industry benchmarks through our proprietary production scheduling algorithms.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque