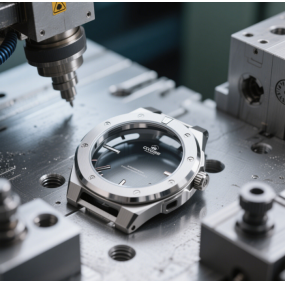

As a leading provider of CNC stainless steel machining, EMAR delivers high-precision components tailored to meet stringent industry standards. Our advanced manufacturing capabilities ensure exceptional surface finishes, tight tolerances, and repeatable quality for critical applications across aerospace, medical, and automotive sectors.

Why Choose CNC Machining for Stainless Steel Components?

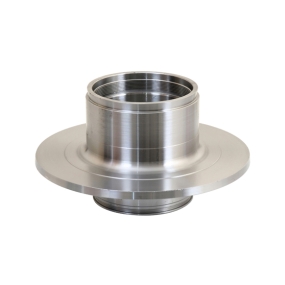

Stainless steel's exceptional corrosion resistance and mechanical properties make it ideal for demanding environments, but its hardness requires specialized CNC machining expertise. Our 5-axis CNC centers equipped with premium tooling overcome machining challenges like work hardening, delivering burr-free parts with complex geometries while maintaining material integrity.

EMAR's Advanced Stainless Steel Machining Capabilities

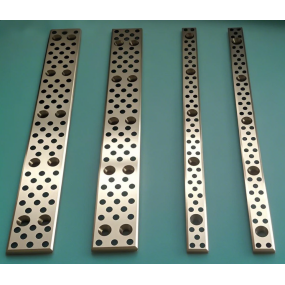

We operate a full range of CNC turning and milling machines capable of processing all stainless steel grades (304, 316, 17-4PH, etc.). Our CNC machining services include:

- High-speed machining for reduced cycle times

- Micro-machining for precision medical components

- Multi-axis simultaneous machining for complex contours

- Secondary operations including deburring and passivation

Quality Assurance and Industry Compliance

Every stainless steel component undergoes rigorous inspection using CMMs and surface testers. EMAR maintains ISO 9001 certification and provides full material traceability with mill test reports, ensuring compliance with ASME, ASTM, and customer-specific standards.

Streamlined Production from Prototype to Volume

From single prototypes to high-volume production runs, our flexible CNC workshop adapts to your project requirements. Our engineering team optimizes machining strategies to balance cost-efficiency with precision, offering DFM feedback to enhance manufacturability.

Contact EMAR at www.sjt-ic.com to discuss your stainless steel machining project. Our technical specialists will provide customized solutions with competitive lead times and transparent pricing.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque