In modern manufacturing, CNC thin sheet machining has become a critical process for industries requiring high-precision, lightweight components. As a leading provider at EMAR (https://www.sjt-ic.com), we specialize in delivering exceptional CNC sheet metal fabrication services that meet stringent tolerance requirements while optimizing production efficiency.

Why Choose CNC for Thin Sheet Metal Fabrication?

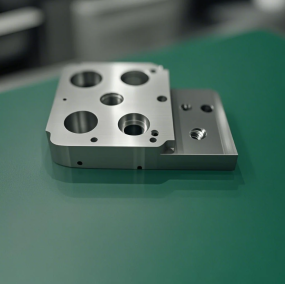

CNC Machining offers unparalleled advantages for thin sheet processing (.5-3mm thickness range):

- ±.01mm dimensional accuracy for critical aerospace/medical components

- Superior surface finishes (Ra .4μm achievable)

- Material versatility including aluminum, stainless steel, titanium, and copper alloys

- Complex geometries with burr-free edges through advanced toolpath programming

EMAR's Advanced Thin Sheet Machining Capabilities

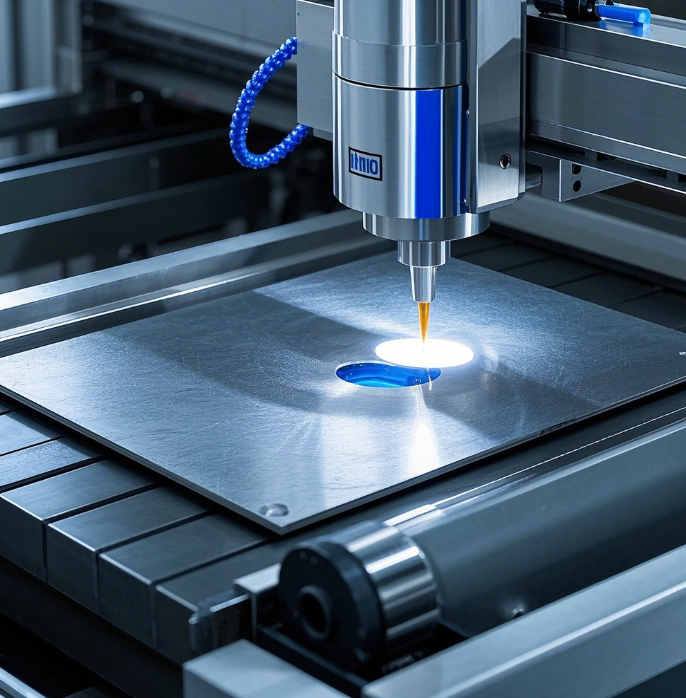

Our facility features 5-axis CNC mills with high-speed spindles (24,000 RPM) specifically configured for thin sheet metal CNC work:

- Vacuum workholding systems preventing material deformation

- Micro-tooling capabilities down to .2mm diameter

- In-process laser measurement for real-time thickness verification

- Automated deburring stations ensuring perfect edge quality

Industry-Specific Applications

We serve diverse sectors with specialized thin sheet solutions:

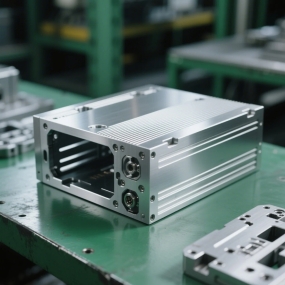

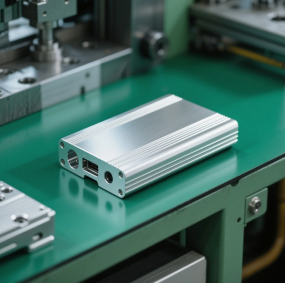

- Electronics: EMI shielding enclosures with vent patterns

- Automotive: Lightweight structural brackets with formed features

- Medical: Surgical instrument components requiring biocompatible finishes

- Aerospace: Fuel system flanges with integrated sealing surfaces

Quality Assurance Protocol

Every thin sheet project undergoes rigorous inspection:

- First-article inspection with CMM verification

- Surface flatness measurement via optical comparators

- Material certification traceability

- DFM feedback during project quoting phase

Contact EMAR's engineering team today to discuss your thin sheet machining requirements. Our combination of advanced CNC technology and material science expertise ensures optimal results for your most challenging applications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque