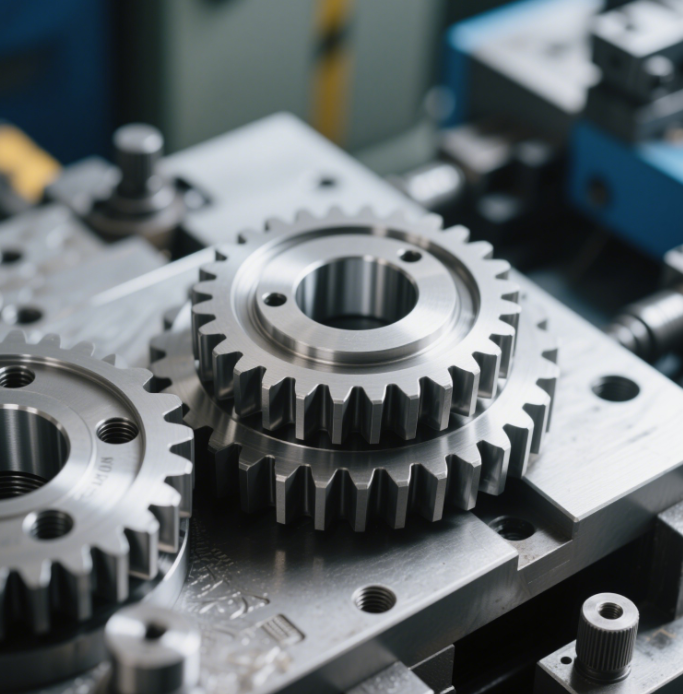

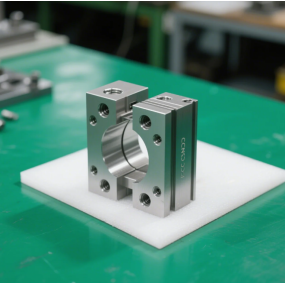

In modern manufacturing, CNC Machining gears is critical for industries requiring high torque transmission and minimal noise. EMAR leverages advanced 5-axis CNC technology to deliver gears with micron-level accuracy, meeting ISO 9001 and AS910 standards.

Why Choose CNC Machining for Gear Manufacturing?

Unlike traditional methods, CNC gear machining ensures perfect tooth profiles, surface finishes (Ra .4μm achievable), and batch consistency. Our Swiss-type lathes and gear hobbing machines produce spur, helical, bevel, and worm gears from materials like 414 steel, brass, and PEEK.

EMAR's 6-Step Gear Production Process

1. Material Certification: Traceable metal/plastic blanks

2. Pre-Turning: ±.01mm OD precision

3. Gear Cutting: .005° indexing accuracy

4. Heat Treatment: Case hardening up to HRC 60

5. Finishing: Grinding/lapping for<1μm runout

6. Quality Control: 100% CMM inspection

Applications of Our CNC Machined Gears

From automotive transmissions to aerospace actuators, EMAR's gears operate flawlessly under extreme conditions. Recent projects include:

- 10,000-piece planetary gear sets for EV reducers (.02mm pitch error)

- Titanium helicopter transmission gears (MIL-STD-153 compliant)

Request a free gear design consultation at www.sjt-ic.com, where our engineers optimize your designs for manufacturability and cost-efficiency.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque