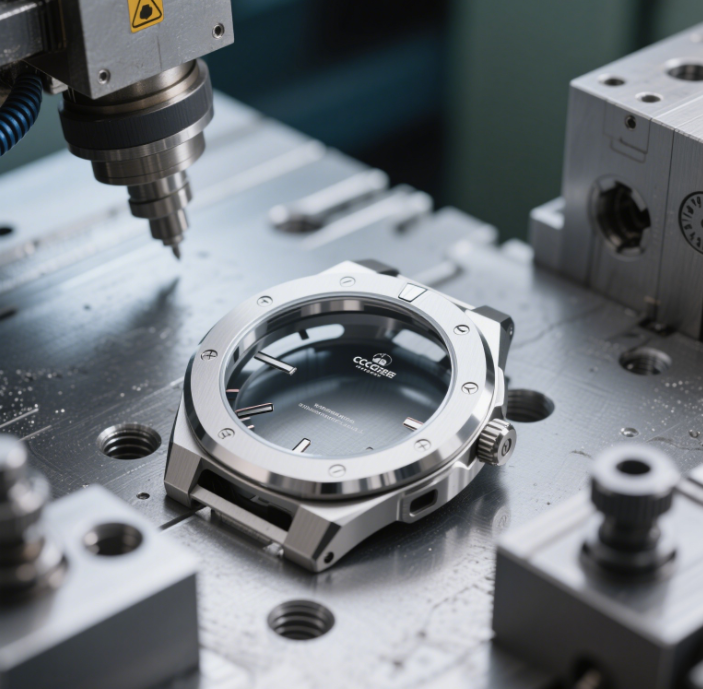

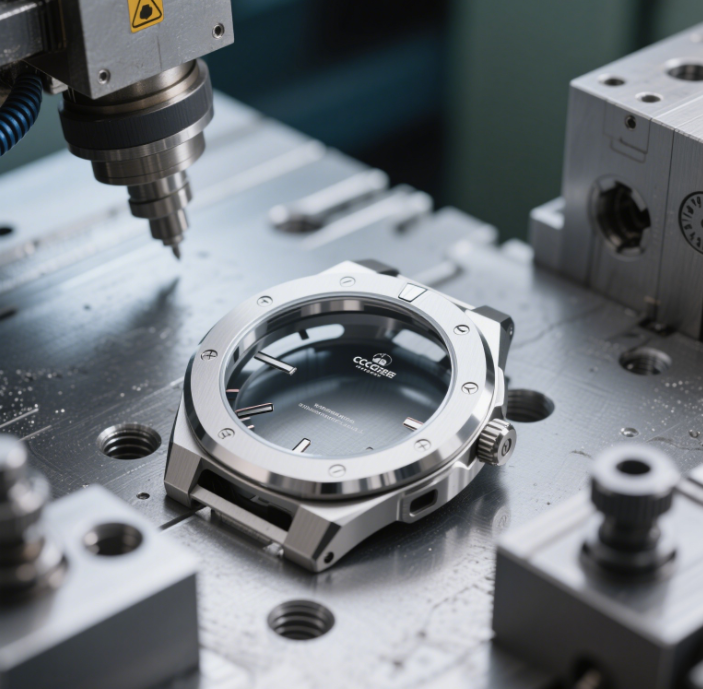

In the competitive world of watch manufacturing, CNC Machining has become the gold standard for producing durable, intricate, and aesthetically pleasing watch cases. At EMAR, we specialize in delivering precision-engineered watch case solutions that meet the exacting standards of luxury timepiece brands and industrial watch manufacturers alike.

Why Choose CNC Machining for Watch Cases?

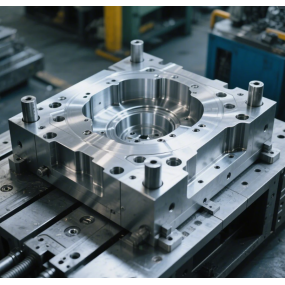

CNC machining offers unparalleled precision when crafting watch cases from materials like stainless steel, titanium, or precious metals. Our advanced 5-axis CNC machines can create complex geometries, perfect bezel angles, and seamless integration points for crowns and pushers - all with micron-level accuracy that ensures perfect water resistance and durability.

Our Watch Case Manufacturing Process

EMAR follows a rigorous production workflow: 1) Material selection and verification, 2) Precision programming using CAD/CAM software, 3) Multi-stage machining process, 4) Surface finishing (brushing, polishing, or coating), and 5) Comprehensive quality inspection. This ensures every watch case meets both dimensional tolerances and cosmetic requirements.

Advantages of Partnering with EMAR

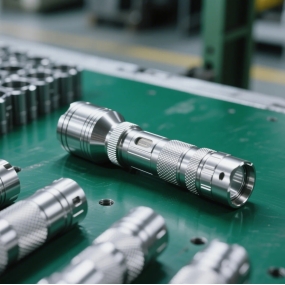

With over 15 years of experience in precision machining, EMAR offers: rapid prototyping capabilities, strict IP protection protocols, material traceability, and the ability to handle both small batches and mass production. Our ISO-certified facility in China combines German-engineered machinery with skilled craftsmanship to deliver watch cases that exceed industry standards.

Customization Options Available

We accommodate various design requirements including: different case shapes (round, square, tonneau), lug designs, caseback engravings, and special surface treatments like PVD coating or diamond-like carbon (DLC) finishes. Our engineering team can advise on optimal designs for both functionality and manufacturing efficiency.

Quality Assurance You Can Trust

Every EMAR-machined watch case undergoes multiple inspections including: coordinate measuring machine (CMM) verification, surface roughness testing, water resistance checks, and visual inspection under magnification. We provide full material certifications and inspection reports with each delivery.

For watch brands seeking a reliable CNC machining partner, EMAR offers the perfect combination of precision engineering, material expertise, and manufacturing flexibility. Contact our technical team today to discuss your specific watch case requirements and receive a competitive quote.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque