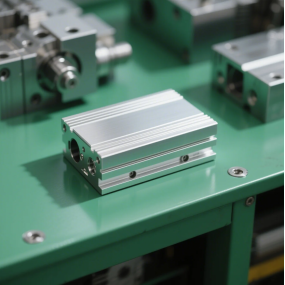

In modern optical and lighting industries, CNC machined reflector cups play a critical role in directing and enhancing light output. As a leading CNC Machining service provider, EMAR specializes in manufacturing reflector cups with micron-level accuracy for automotive, aerospace, and architectural lighting applications.

Why Choose CNC Machining for Reflector Cups?

CNC technology enables the production of reflector cups with complex parabolic geometries that traditional methods cannot achieve. Our 5-axis CNC machines maintain ±.01mm tolerances while processing aluminum, copper, and engineering plastics. The automated process ensures batch-to-batch consistency crucial for optical performance.

EMAR's Advanced Manufacturing Capabilities

Our facility features:

- High-speed machining centers with 20,000 RPM spindles

- In-process measurement systems for real-time quality control

- Mirror-finish polishing (Ra .2μm max) for optimal reflectivity

Material Selection for Optical Performance

We recommend:

- Aluminum 6061-T6: Best cost-performance ratio with 92% reflectivity after polishing

- Oxygen-free copper: 98% reflectivity for high-end applications

- PEEK: For high-temperature environments up to 250°C

EMAR's engineering team works closely with clients to optimize designs for manufacturability and optical efficiency. Our ISO 9001-certified processes guarantee that every reflector cup meets stringent industry standards while maintaining competitive lead times of 2-3 weeks for prototypes.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque