EMAR specializes in high-precision automotive parts CNC Machining, delivering customized solutions for OEMs and suppliers. Our advanced CNC technology ensures tight tolerances, superior surface finishes, and repeatable quality for critical vehicle components.

Why Choose CNC Machining for Automotive Components?

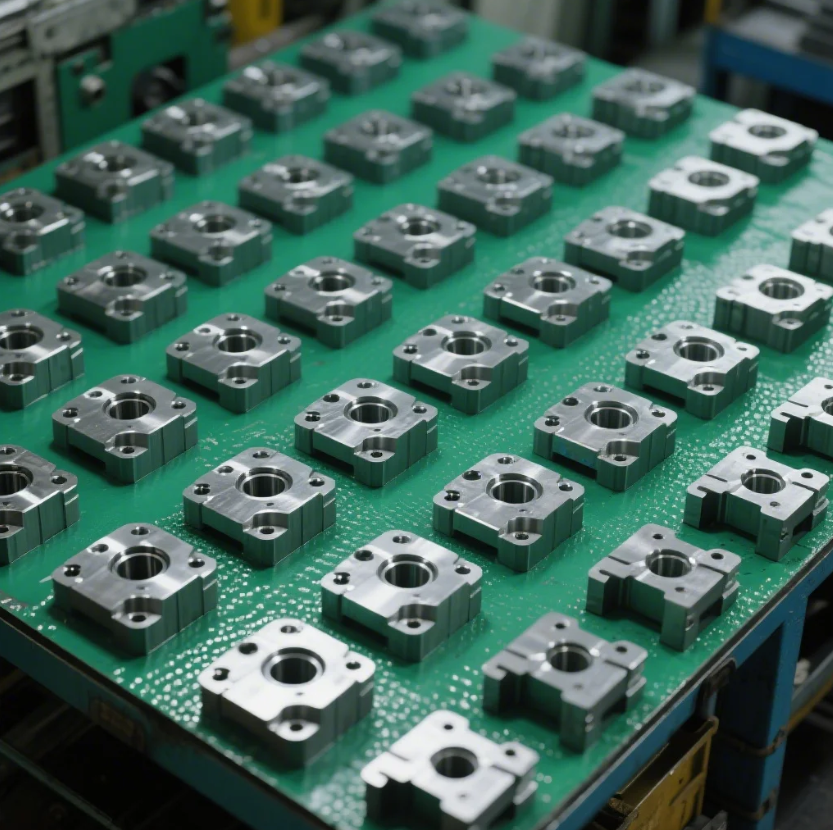

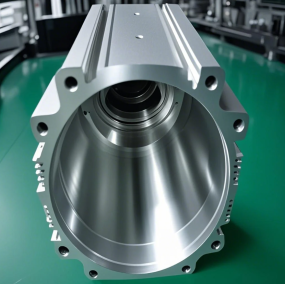

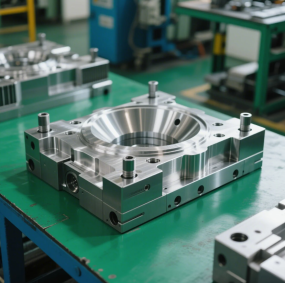

Modern vehicles require components with micron-level accuracy. Our 5-axis CNC machines produce complex geometries like engine blocks, transmission housings, and brake calipers with .005mm precision. The automated process guarantees consistency across mass production runs.

EMAR's Automotive CNC Capabilities

We operate a 15,000㎡ facility equipped with 42 CNC centers featuring:

- Multi-axis simultaneous machining

- In-process quality monitoring

- Aluminum/steel/titanium expertise

All processes comply with IATF 16949 automotive quality standards.

Material Selection for Auto Parts CNC Machining

We machine all industry-standard materials including:

- Aluminum 6061-T6 (most common)

- Stainless steel 303/304

- Carbon steel 1045

- Brass C360

Our engineers help select optimal materials balancing cost, strength, and machinability.

Surface Treatment Options

Post-machining services include:

- Anodizing (Type II/III)

- Powder coating

- Electroplating

- Passivation

These enhance corrosion resistance and aesthetic appeal.

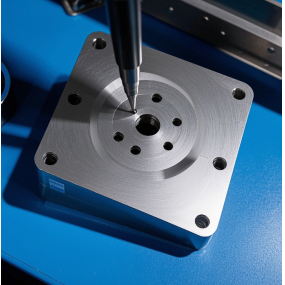

Quality Assurance Process

Every CNC machined automotive part undergoes:

- First-article inspection

- In-process dimensional checks

- Final CMM verification

- Material certification

We provide full PPAP documentation upon request.

Visit EMAR's official website to request a free project evaluation. Our engineering team responds within 24 hours with DFM analysis and competitive pricing.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque