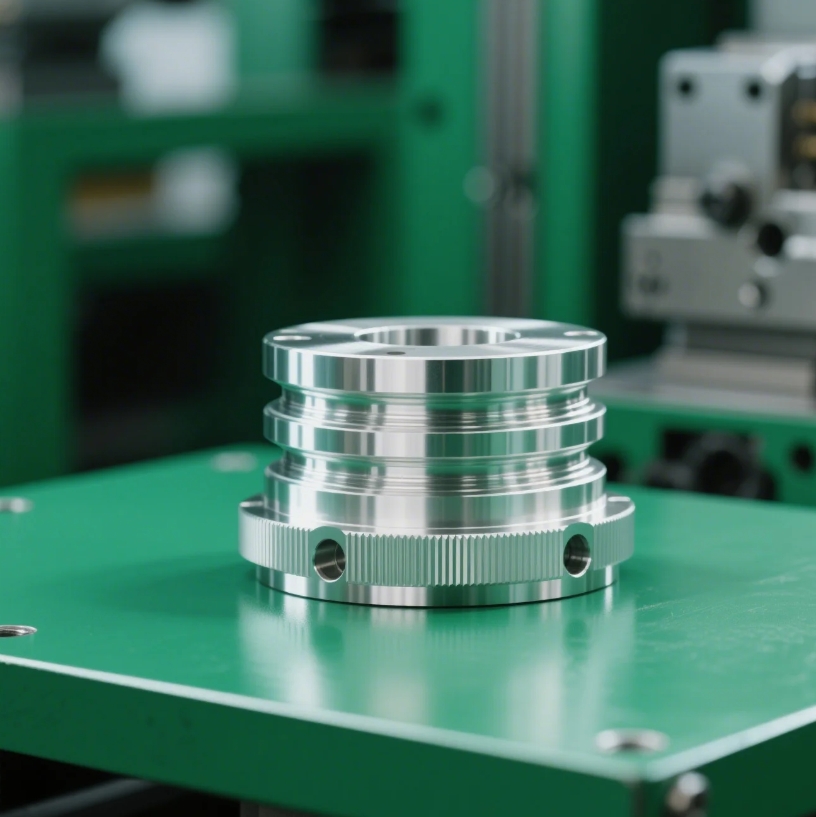

In modern manufacturing, CNC Machining aluminum alloys has become a critical process for industries requiring high strength-to-weight ratios and corrosion resistance. As a leading provider at EMAR, we specialize in delivering precision-machined aluminum components tailored to aerospace, automotive, and electronics sectors.

Why Choose CNC Machining for Aluminum Alloys?

Aluminum's machinability makes it ideal for CNC precision machining, offering faster production cycles compared to steel. Our 5-axis CNC centers achieve ±.01mm tolerances while maintaining superior surface finishes, eliminating secondary processing for most applications.

EMAR's Advanced Aluminum Machining Capabilities

We employ proprietary toolpath strategies to prevent common aluminum machining challenges like built-up edge. Our facility features:

- High-speed spindles (15,000+ RPM) for thin-wall machining

- Cryogenic cooling systems for thermal stability

- In-process measurement with automated compensation

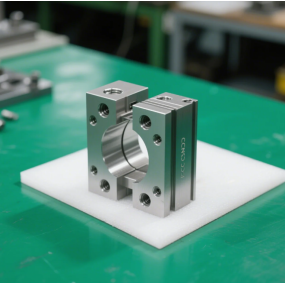

Industry-Specific Aluminum Machining Solutions

From 6061-T6 structural components to 7075 aerospace fittings, we optimize aluminum CNC machining parameters for each alloy grade. Our engineers collaborate with clients to balance cost-efficiency with performance requirements, whether for prototyping or mass production.

Discover how EMAR's ISO 9001-certified CNC machining services can elevate your aluminum component quality while reducing lead times by 30-40%. Request a free project evaluation today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque