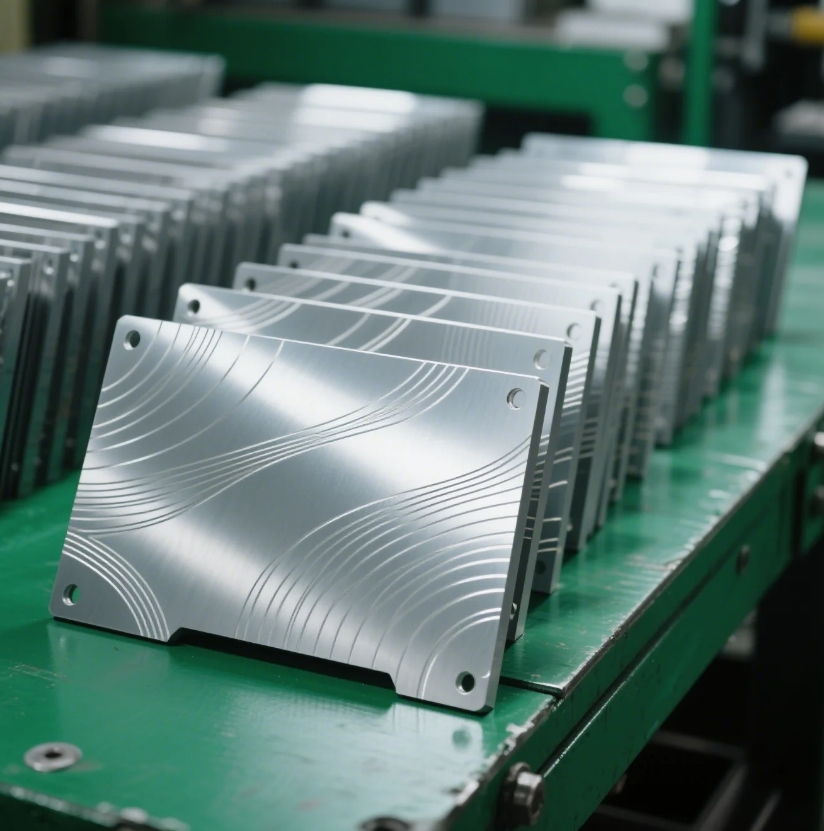

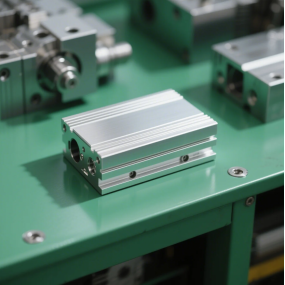

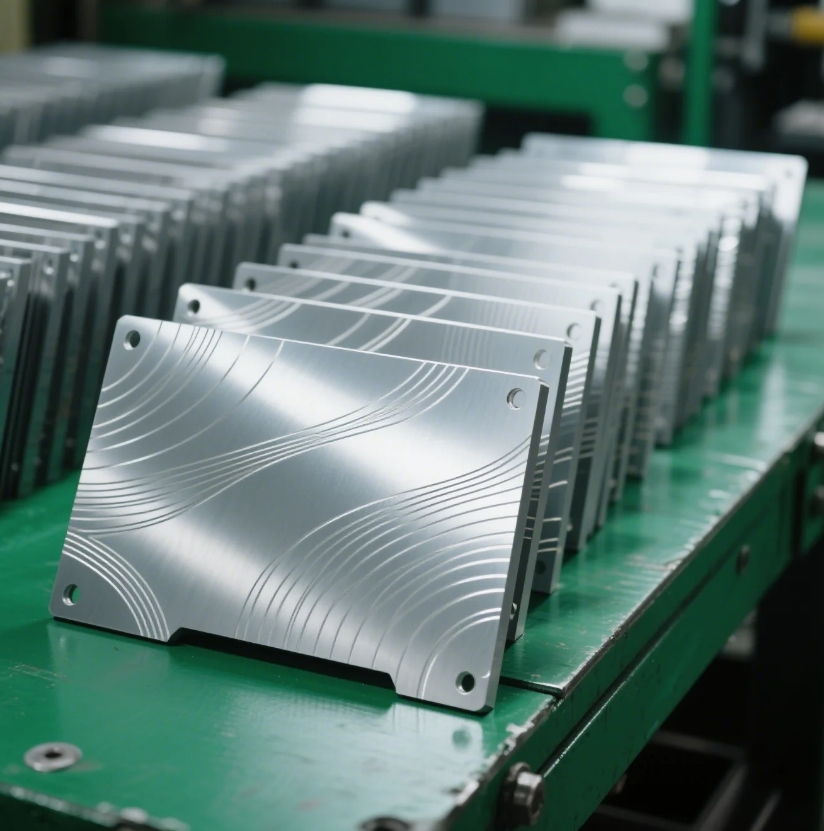

CNC machining aluminum plates is one of the most common manufacturing processes across industries due to aluminum's excellent machinability, strength-to-weight ratio, and corrosion resistance. As a CNC machining expert at EMAR, we specialize in transforming aluminum plates into precision components for aerospace, automotive, electronics, and more.

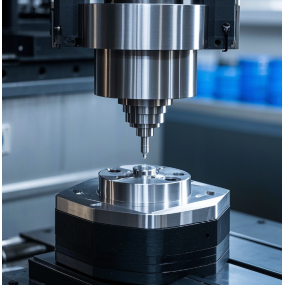

Key Methods for CNC Machining Aluminum Plates

There are several fundamental methods we employ when working with aluminum plates:

- Milling: Our 3-5 axis CNC milling machines create complex geometries with tight tolerances (±.005mm)

- Turning: For cylindrical parts, our CNC lathes deliver exceptional surface finishes

- Drilling & Tapping: Precision hole-making with optimized tool paths to prevent burring

- Contouring: Creating intricate 2D and 3D profiles from aluminum plate stock

Material Considerations

We work with various aluminum grades, each offering unique benefits:

- 6061-T6: Most common, excellent all-around properties

- 7075: Higher strength for aerospace applications

- 5052: Superior corrosion resistance

- 2024: High fatigue resistance

EMAR's Advanced Capabilities

At EMAR, we've optimized our aluminum plate machining processes with:

- High-speed machining centers (up to 20,000 RPM)

- Advanced coolant systems to prevent heat distortion

- In-process inspection with CMM and optical comparators

- Custom fixturing solutions for thin-wall aluminum parts

Quality Assurance

Every aluminum component undergoes rigorous inspection:

- Dimensional verification to engineering drawings

- Surface finish measurement (Ra .4-3.2 μm achievable)

- Material certification verification

- First article inspection reports available

Why Choose EMAR for Your Aluminum CNC Needs

With over 15 years specializing in precision CNC machining, EMAR offers:

- Fast turnaround (prototypes in 3-5 days, production in 2 weeks)

- Competitive pricing with volume discounts

- DFM (Design for Manufacturing) consulting

- Complete secondary operations (anodizing, painting, assembly)

- ISO 9001:2015 certified quality system

For your next aluminum plate machining project, contact EMAR's technical team at www.sjt-ic.com for a free quote and manufacturing consultation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque