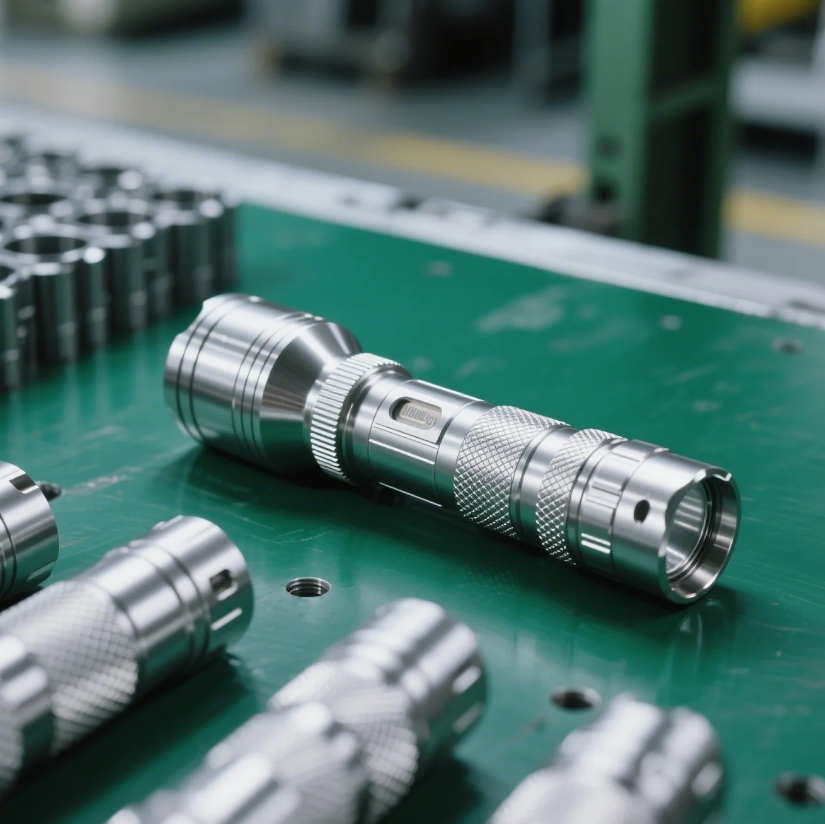

Introduction to CNC Machined Flashlights

When it comes to manufacturing high-quality flashlights, CNC Machining offers unparalleled precision and durability. At EMAR, we specialize in producing premium flashlight components and complete assemblies using advanced CNC technology. Our CNC machining capabilities ensure each flashlight meets exact specifications for performance, reliability, and longevity.

Why Choose CNC Machining for Flashlight Production?

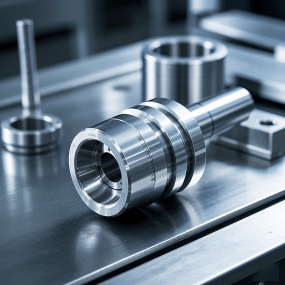

CNC machining provides several critical advantages for flashlight manufacturing:

- Precision Tolerances: Achieve perfect fits for threads, O-rings, and battery compartments

- Material Versatility: Work with aluminum, titanium, stainless steel, and specialty alloys

- Surface Finish Options: From smooth anodized finishes to textured grips

- Thermal Management: Optimized heat dissipation for high-power LED units

Our CNC Flashlight Manufacturing Process

EMAR follows a rigorous production workflow to ensure top-quality flashlight components:

- Material selection and verification

- Precision CNC turning and milling operations

- Thread cutting and chamfering

- Surface treatment (anodizing, plating, or polishing)

- Quality inspection and testing

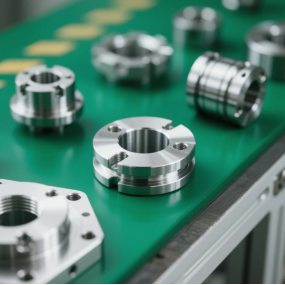

Custom Flashlight Solutions

We offer comprehensive CNC machining services for custom flashlight designs:

- Tactical and military-grade flashlights

- EDC (Everyday Carry) compact models

- Specialized industrial lighting solutions

- Luxury and collector-grade pieces

Quality Assurance in Flashlight Manufacturing

Every flashlight component undergoes strict quality control measures:

- Dimensional verification with CMM equipment

- Thread gauge testing for proper engagement

- Water resistance validation

- Drop and impact testing

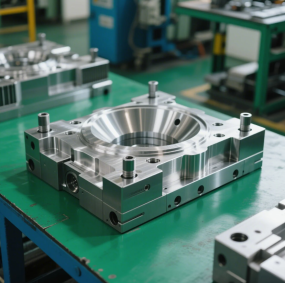

Why Partner with EMAR for Your Flashlight Needs?

EMAR stands out in the CNC machining industry with:

- State-of-the-art CNC equipment (5-axis machining centers)

- Experienced engineering team for design optimization

- Competitive pricing for both prototypes and production runs

- Fast turnaround times without compromising quality

Get Started with Your Flashlight Project

Contact EMAR today to discuss your CNC machined flashlight requirements. Our team is ready to provide expert guidance from design through production, ensuring you receive premium components that meet your exact specifications.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque