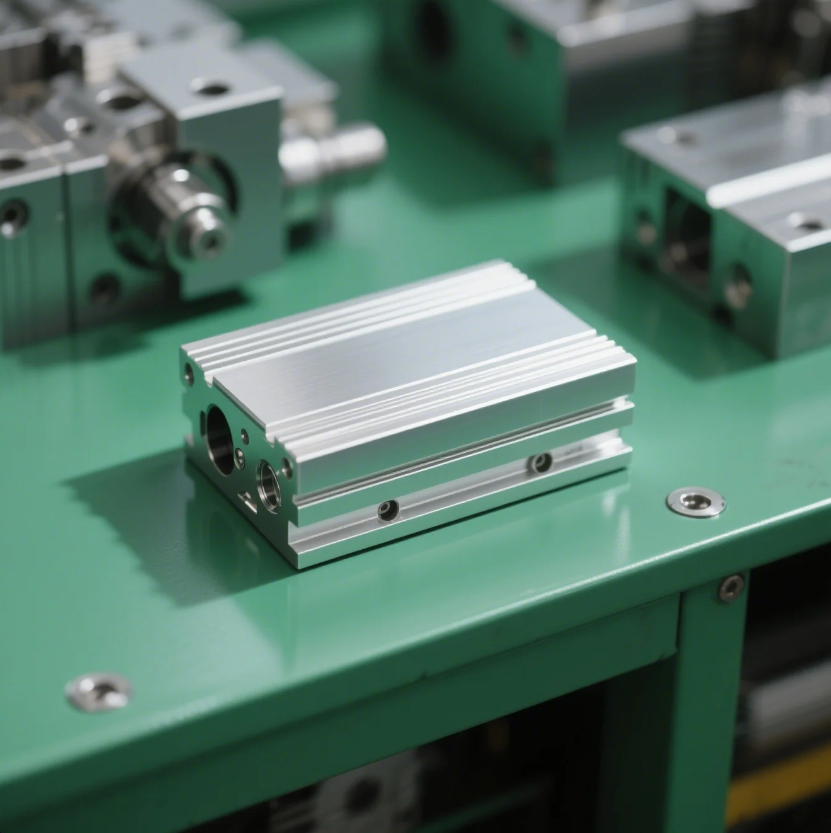

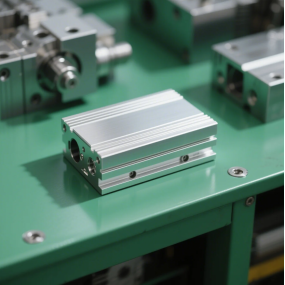

As a leading CNC Machining service provider, EMAR specializes in aluminum enclosure CNC machining solutions for industries ranging from electronics to aerospace. Our advanced 5-axis CNC systems and ISO 9001-certified processes ensure precision down to ±.01mm.

Why Choose CNC Machining for Aluminum Enclosures?

Aluminum remains the top material choice for protective enclosures due to its ideal strength-to-weight ratio and EMI shielding properties. Our CNC machining process delivers:

- Superior dimensional accuracy for perfect component fitment

- Complex geometries including integrated cooling fins and cable ports

- Surface finishes from bead-blasted to anodized (up to MIL-A-8625 standards)

- Rapid prototyping to full production runs (500+ units/week capacity)

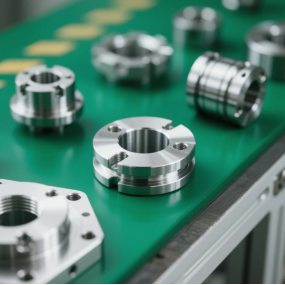

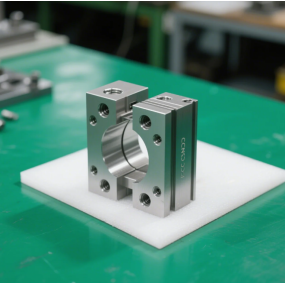

EMAR's Technical Capabilities

Our 15,000㎡ facility features:

- 12 Mazak 5-axis CNC machining centers

- In-house CMM inspection (Zeiss CONTURA G2)

- Material options: 6061-T6, 7075, 5052 aluminum alloys

- Tolerance: ±.005" (±.13mm) standard, ±.001" (±.025mm) upon request

End-to-End Manufacturing Process

From design review to final delivery, our aluminum enclosure CNC machining workflow includes:

- DFM analysis with our engineering team

- Program optimization using Mastercam 2024

- First-article inspection (FAI) reporting

- IPQC at 3 critical checkpoints

- 100% final dimensional verification

Trust EMAR for mission-critical aluminum enclosures that meet MIL-STD-810G standards. Request your instant quote with 24-hour response guarantee.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque