In today's competitive manufacturing landscape, CNC precision parts machining has become the gold standard for industries demanding micron-level accuracy and repeatability. As a leading CNC Machining service provider, EMAR Company combines advanced technology with engineering expertise to deliver flawless components for aerospace, automotive, medical, and industrial applications.

What is CNC Precision Parts Machining?

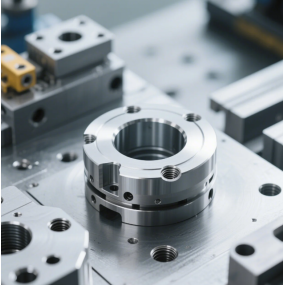

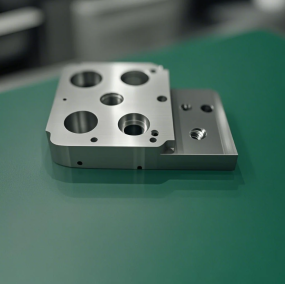

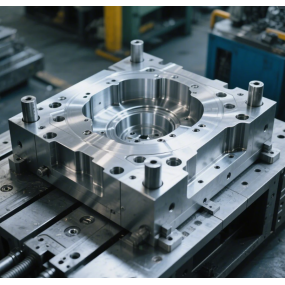

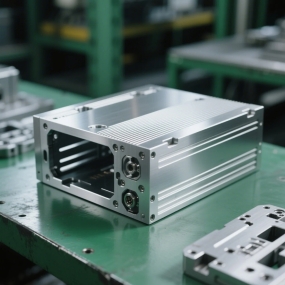

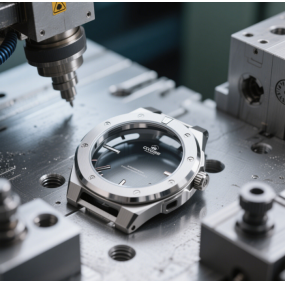

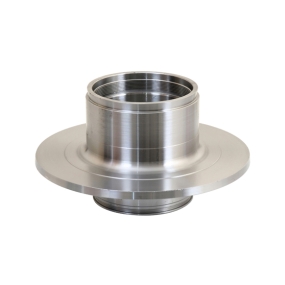

CNC precision parts machining refers to the computer-controlled subtractive manufacturing process that produces complex components with tolerances as tight as ±.001 inches. Our 5-axis CNC milling centers and Swiss-type lathes at EMAR transform raw materials (aluminum, titanium, stainless steel, plastics) into finished parts with exceptional surface finishes and geometric precision.

Why Choose EMAR for Your Precision Machining Needs?

1. Advanced Equipment: Our facility houses 30+ CNC machines including Mazak Integrex and DMG Mori systems with live tooling capabilities

2. Material Expertise: We machine over 50+ metal alloys and engineering-grade plastics

3. Quality Assurance: ISO 9001:2015 certified with in-house CMM inspection (Mitutoyo)

4. Rapid Prototyping: 3-5 day turnaround for prototype batches

5. Cost Optimization: DFM analysis to reduce your part costs by up to 40%

Applications of Precision CNC Machined Parts

Our CNC precision parts serve critical functions across industries:

- Aerospace: Engine components, landing gear parts

- Medical: Surgical instruments, implantable devices

- Automotive: Fuel injection systems, transmission components

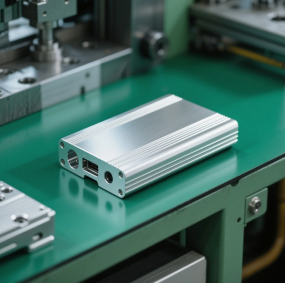

- Electronics: Heat sinks, connector housings

Visit EMAR's official website to request a free project evaluation and discover how our CNC machining solutions can elevate your manufacturing outcomes.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque