As a leading CNC Machining service provider, EMAR specializes in high-precision mold manufacturing for industries ranging from automotive to aerospace. Our advanced CNC technology ensures unmatched accuracy and repeatability in every mold we produce.

Why Choose CNC Machining for Mold Manufacturing?

CNC machining offers significant advantages for mold production compared to traditional methods. The computer-controlled process delivers:

- ±.005mm dimensional accuracy

- Superior surface finishes (up to Ra .2μm)

- Complex geometries impossible with manual machining

- Faster production cycles

- Excellent consistency across production runs

Our CNC Mold Manufacturing Process

EMAR follows a rigorous mold manufacturing process to ensure quality:

- Design Analysis: Our engineers review your 3D models for manufacturability

- Material Selection: Choosing optimal tool steel, aluminum, or other alloys

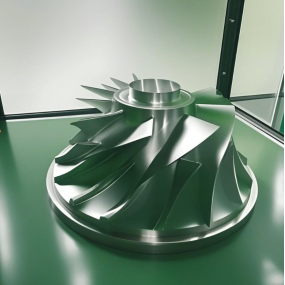

- Precision Machining: 5-axis CNC milling for complex cavities and cores

- Surface Treatment: Polishing, texturing, or coating as required

- Quality Inspection: CMM verification and trial molding

Materials for CNC Machined Molds

We work with various mold-grade materials including:

- P20, H13, and S7 tool steels

- Aluminum 6061 and 7075

- Stainless steel series

- Copper alloys for thermal management

EMAR's Advantages in CNC Mold Making

Our CNC machining capabilities set us apart:

- 20+ years of mold manufacturing experience

- State-of-the-art 5-axis CNC machining centers

- ISO 9001 certified quality management

- Quick-turn prototyping services

- Competitive pricing for production quantities

For your next mold project, trust EMAR's CNC machining expertise. Contact our engineering team today to discuss your requirements and receive a free quote.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque