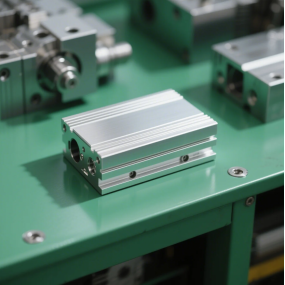

As a professional CNC chassis machining provider, EMAR delivers high-precision components for industries ranging from telecommunications to industrial automation. Our advanced CNC technology ensures tight tolerances and superior surface finishes for complex chassis designs.

Why Choose CNC Machining for Chassis Production?

CNC chassis machining offers unparalleled advantages over traditional manufacturing methods. The computer-controlled process guarantees dimensional accuracy within ±.01mm, critical for proper component fitment and electromagnetic shielding performance. Our 5-axis CNC machines can create intricate geometries including ventilation patterns, cable routing channels, and mounting interfaces in a single setup.

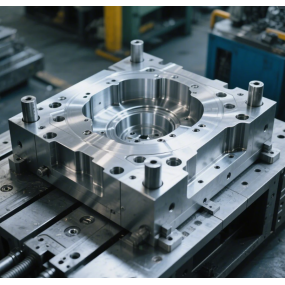

EMAR's CNC Chassis Machining Capabilities

Our facility features state-of-the-art CNC machining centers specifically configured for chassis manufacturing:

- Multi-axis simultaneous machining for complex contours

- High-speed spindles (up to 20,000 RPM) for efficient material removal

- Automated tool changers with 30+ tool capacity

- In-process quality verification systems

Material Selection for Optimal Performance

We machine chassis components from various materials including aluminum alloys (6061, 7075), stainless steel, and engineering plastics. Our engineers will recommend the optimal material based on your requirements for strength, weight, thermal management, and cost efficiency.

Quality Assurance Process

Every chassis undergoes rigorous inspection using coordinate measuring machines (CMM) and surface roughness testers. EMAR maintains ISO 9001 certification, ensuring consistent quality across production batches.

For your CNC chassis machining needs, contact EMAR at www.sjt-ic.com to discuss your project requirements and receive a competitive quotation.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque