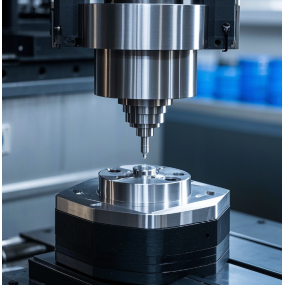

As a leading CNC Machining service provider, EMAR specializes in precision manufacturing of challenging materials like beryllium copper. This guide explores the technical considerations and best practices for machining this high-performance alloy.

Understanding Beryllium Copper Properties

Beryllium copper (BeCu) is a non-sparking metal with exceptional strength, thermal conductivity, and corrosion resistance. These properties make it ideal for aerospace, electronics, and oil/gas applications, but require specific machining approaches.

Key Challenges in CNC Machining Beryllium Copper

1. Tool wear: The alloy's hardness accelerates tool degradation

2. Heat generation: Requires precise cooling strategies

3. Safety precautions: Necessary due to beryllium content

EMAR's Proven Machining Process

Our ISO-certified facility implements:

- Rigid machine setups to minimize vibration

- Carbide tools with specialized coatings

- High-pressure coolant systems

- Dust collection systems for operator safety

Why Choose EMAR for Your Beryllium Copper Projects?

With 15+ years of experience in precision CNC machining, we offer:

• Material-specific machining parameters database

• ±.005mm tolerance capabilities

• Full-spectrum post-processing services

• DFM support from our engineering team

Visit EMAR's official website to request a quote or technical consultation for your next beryllium copper component.

English

English » »

» »

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque