In the fast-evolving automotive industry, precision and reliability are non-negotiable. CNC automotive parts machining plays a pivotal role in manufacturing high-performance components that meet stringent industry standards. At EMAR, we specialize in delivering top-tier CNC Machining services tailored for automotive applications, ensuring durability, accuracy, and cost-efficiency.

Why Choose CNC Machining for Automotive Parts?

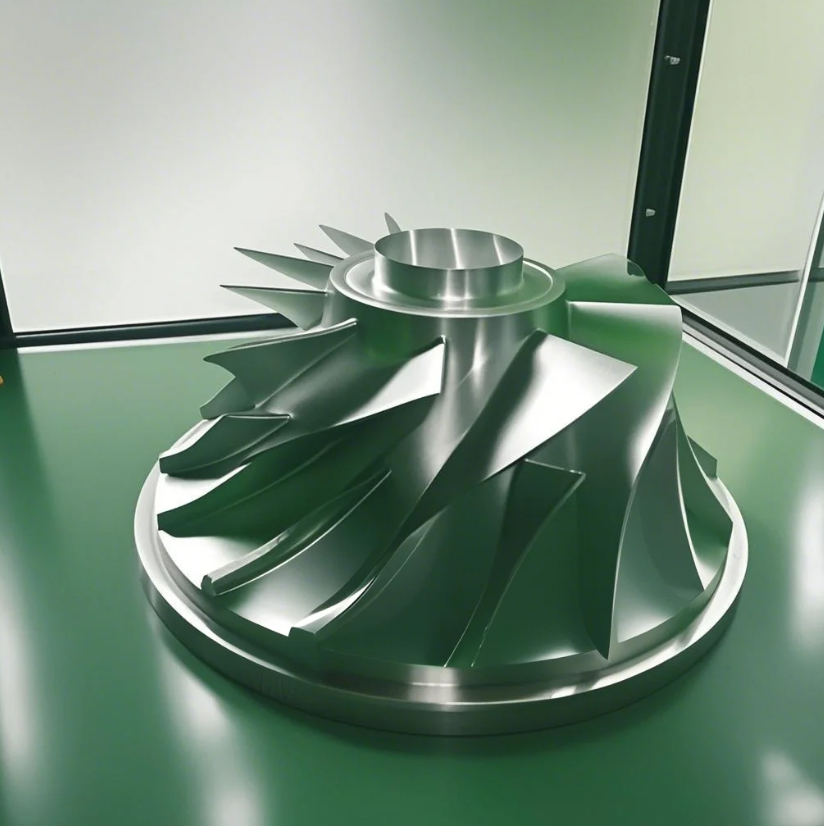

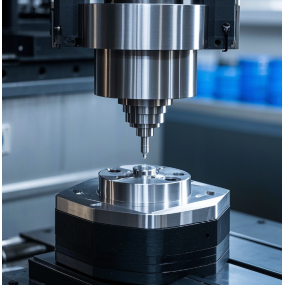

Modern vehicles demand components with micron-level precision to ensure safety and performance. CNC machining offers unmatched consistency in producing complex geometries like engine blocks, transmission housings, and brake system parts. Our advanced 5-axis CNC machines at EMAR handle everything from prototyping to mass production, reducing lead times while maintaining ISO 9001-certified quality.

Key Applications in the Automotive Sector

1. Engine Components: Cylinder heads, pistons, and valve bodies machined from aluminum or titanium alloys.

2. Suspension Systems: Precision-machined control arms and knuckles for optimal weight-to-strength ratios.

3. Electrification Parts: Battery enclosures and motor housings for EVs with tight tolerance requirements.

EMAR's Competitive Edge in Automotive CNC Machining

With 15+ years of expertise, EMAR stands out through:

• Material versatility: Aluminum 6061-T6, stainless steel, PEEK, and custom alloys

• Surface finishing options: Anodizing, powder coating, and electropolishing

• Full-service support: From DFM analysis to just-in-time delivery

Explore how our CNC machining solutions can optimize your automotive supply chain. Request an instant quote today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque