In today's competitive manufacturing landscape, selecting the right CNC precision parts manufacturer is critical for ensuring product quality, efficiency, and cost-effectiveness. EMAR, a trusted name in CNC Machining, delivers unparalleled expertise to meet your industrial needs. This article explores why partnering with a professional manufacturer like EMAR can transform your production process.

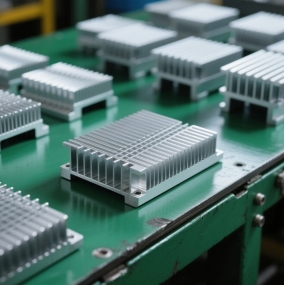

1. Unmatched Precision and Consistency

Advanced CNC machines at EMAR achieve micron-level accuracy, ensuring every component meets strict tolerances. Our ISO-certified processes guarantee repeatable results across high-volume production runs.

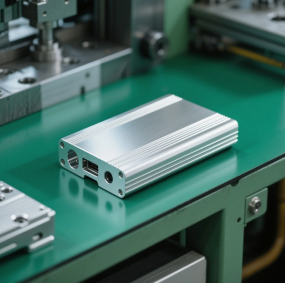

2. Material Versatility for Complex Applications

From aerospace-grade aluminum to medical-grade titanium, our multi-axis machining capabilities handle diverse materials while maintaining structural integrity and surface finish requirements.

3. Streamlined Production Workflow

EMAR's integrated approach combines CAD/CAM programming with automated quality checks, reducing lead times by 30-40% compared to conventional manufacturers. Our just-in-time manufacturing minimizes your inventory costs.

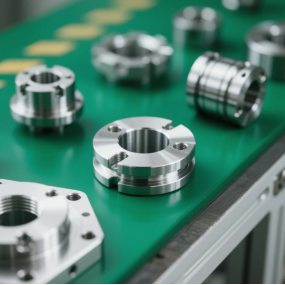

4. Cost-Effective Solutions Without Compromise

Through optimized tool paths and lean manufacturing principles, we deliver competitive pricing for both prototyping and mass production while maintaining military-grade quality standards.

5. End-to-End Technical Support

Our engineering team provides DFM (Design for Manufacturing) analysis, material selection guidance, and post-processing recommendations to ensure optimal performance of your machined components.

As a full-service CNC precision parts manufacturer, EMAR combines cutting-edge technology with decades of machining expertise. Visit www.sjt-ic.com to discover how our solutions can elevate your supply chain reliability and product performance.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque