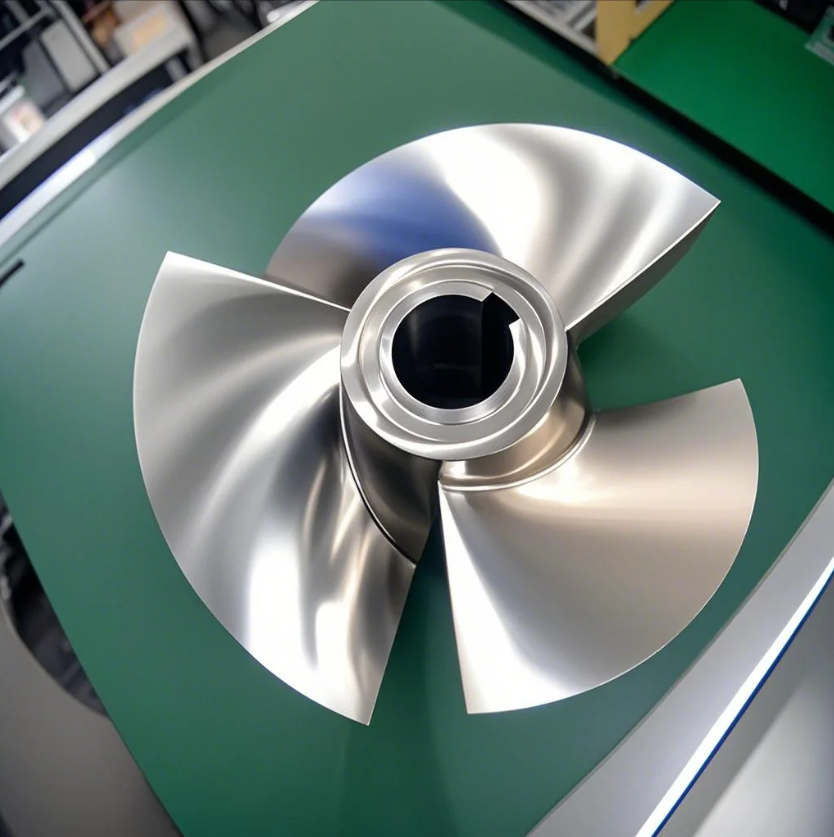

In industries where performance and reliability are non-negotiable, CNC Machining turbine blades stands as a critical manufacturing process. As a leading provider of precision CNC solutions, EMAR combines advanced technology with aerospace-grade expertise to deliver turbine components that meet stringent tolerances and operational demands.

Why CNC Machining is Ideal for Turbine Blade Production

Turbine blades operate under extreme conditions—high temperatures, rotational stresses, and corrosive environments. CNC machining enables:

-

±.005mm dimensional accuracy for aerodynamic efficiency

-

Superior surface finishes (Ra .4μm achievable)

-

Complex internal cooling channel fabrication

-

Material integrity preservation in nickel alloys/Ti-6Al-4V

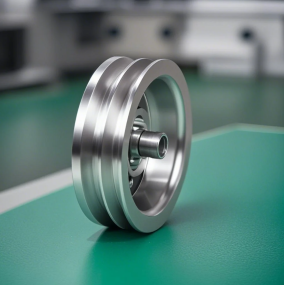

EMAR's 5-Axis CNC Capabilities for Turbine Components

Our facility features:

-

Mikron HSM 600U (20,000 RPM spindle speed)

-

DMG MORI 5-axis simultaneous machining

-

On-machine probing for real-time quality control

-

Adaptive machining for distortion compensation

Material Expertise for Demanding Applications

We specialize in machining:

-

Turbine blades from Inconel 718, Rene 41, CMSX-4 single crystals

-

Compressor blades in titanium alloys

-

Stator vanes with thermal barrier coatings

Quality Assurance That Meets Aviation Standards

Every component undergoes:

-

CMM inspection (Zeiss CONTURA G2)

-

Surface roughness analysis

-

X-ray diffraction for residual stress measurement

-

AS910-compliant documentation

For turbine blade projects requiring unparalleled precision, EMAR's CNC machining services provide the technological edge. Our engineers welcome complex challenges—contact us to discuss your specific blade profile requirements and performance criteria.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque