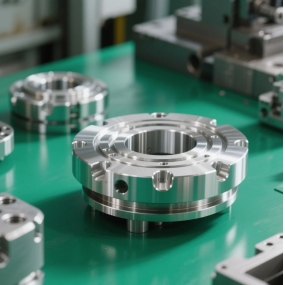

In the realm of high-performance mechanical systems, CNC Machining flywheel components has become a critical process for industries demanding reliability and precision. As a leading CNC machining service provider, EMAR specializes in manufacturing flywheels that meet stringent tolerances and durability requirements for automotive, aerospace, and industrial applications.

Why Choose CNC Machining for Flywheel Production?

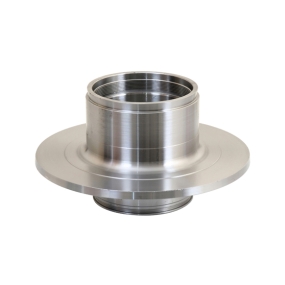

Flywheels serve as energy storage devices in engines and machinery, requiring exceptional balance and material integrity. CNC machining offers unparalleled advantages for flywheel manufacturing:

- Micro-level precision: Achieves concentricity within .005mm for vibration-free operation

- Material versatility: Processes cast iron, steel alloys, and advanced composites

- Surface finish excellence: Delivers Ra .8μm or better for reduced friction

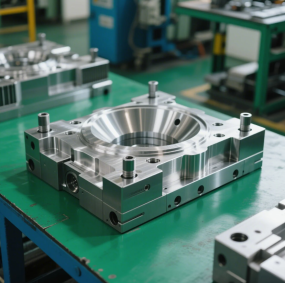

EMAR's Advanced Flywheel Machining Capabilities

Our 5-axis CNC machining centers equipped with live tooling can complete complex flywheel geometries in single setups, ensuring:

- True positional accuracy of mounting holes

- Perfectly balanced mass distribution

- Heat-treated surface hardening when required

Quality Assurance Protocols

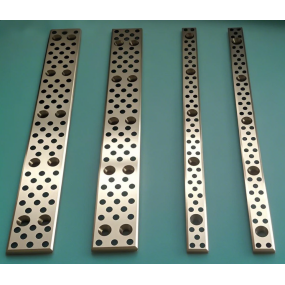

Every flywheel undergoes rigorous inspection including:

- CMM verification of dimensional accuracy

- Dynamic balancing testing up to 10,000 RPM

- Material certification and traceability

With ISO 9001-certified processes and AS910 compliance for aerospace applications, EMAR delivers flywheels that exceed industry standards. Contact our engineering team at www.sjt-ic.com to discuss your project requirements.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque