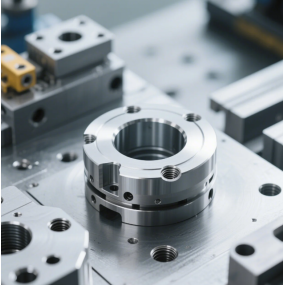

In modern industrial automation, CNC lead screw machining plays a pivotal role in converting rotational motion into precise linear movement. As a specialized CNC Machining service provider, EMAR leverages advanced multi-axis CNC systems to manufacture high-tolerance lead screws for applications ranging from 3D printers to aerospace actuators.

Why Choose CNC Machining for Lead Screws?

Unlike traditional manufacturing methods, CNC lead screw machining offers micron-level accuracy (typically ±.005mm) and superior surface finishes (Ra .8-1.6μm). Our 5-axis CNC machines can produce complex ACME, trapezoidal, or ball screw profiles in one setup, ensuring perfect thread form consistency across the entire length.

Material Selection for Optimal Performance

We machine lead screws from various materials including:

- Carbon steel (for general industrial applications)

- Stainless steel (corrosion-resistant solutions)

- Titanium alloys (aerospace-grade components)

- Brass/bronze (low-friction requirements)

Each material undergoes strict pre-machining stress relief treatment to prevent deformation.

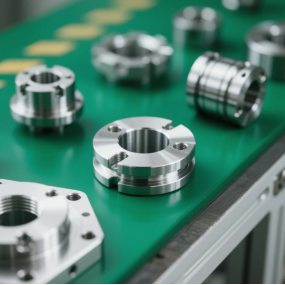

EMAR's Quality Assurance Process

Every CNC machined lead screw undergoes:

- Thread profile inspection using optical comparators

- Hardness testing (HRC 58-62 for hardened steels)

- Runout measurement with CMM equipment

- Dynamic load testing (for critical applications)

Our ISO 9001-certified process ensures consistent quality across production batches.

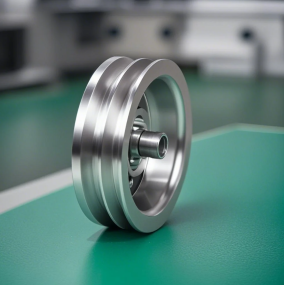

Applications Across Industries

EMAR's CNC lead screws power precision motion systems in:

- Medical equipment (linear actuators for imaging systems)

- Semiconductor manufacturing (wafer handling robots)

- Automotive (electric vehicle battery assembly lines)

- Defense systems (weapon positioning mechanisms)

With 15+ years of CNC machining expertise, EMAR delivers lead screws with exceptional dimensional stability and wear resistance. Contact our engineering team today to discuss your project's specific tolerance requirements and volume needs.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque