In modern manufacturing, CNC Machining pulley components is critical for industries requiring high precision and durability. EMAR, a trusted CNC machining specialist, delivers custom pulley solutions tailored to your exact specifications.

Why Choose CNC Machining for Pulleys?

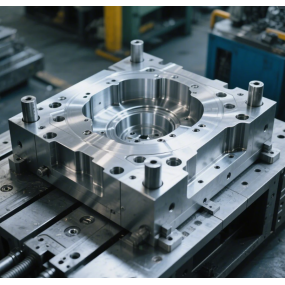

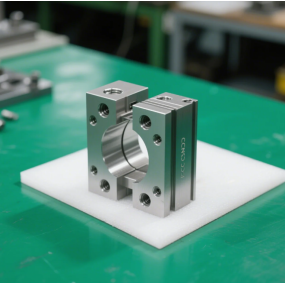

CNC technology ensures unmatched accuracy in producing pulleys with complex geometries, tight tolerances, and smooth surface finishes. Our advanced 5-axis CNC machines handle materials like aluminum, stainless steel, and engineered plastics, guaranteeing optimal performance for power transmission systems.

EMAR's CNC Pulley Manufacturing Process

1. Material selection: We help clients choose the ideal metal or polymer based on load capacity and environmental factors.

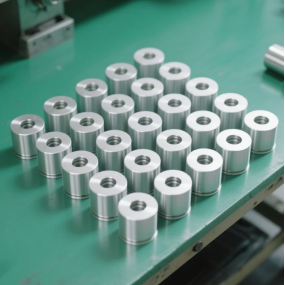

2. Precision machining: Our CNC centers create flawless grooves and bore holes with ±.01mm accuracy.

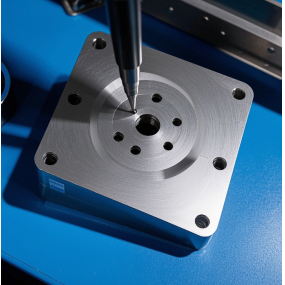

3. Quality inspection: Each pulley undergoes rigorous dimensional and dynamic balancing tests.

Advantages of Partnering with EMAR

• 15+ years of CNC machining expertise in power transmission components

• ISO 9001-certified production facility

• Rapid prototyping to mass production capabilities

• Competitive pricing with 30-day lead time guarantee

Applications Across Industries

Our CNC-machined pulleys serve automotive timing systems, conveyor equipment, agricultural machinery, and marine applications. The corrosion-resistant variants are particularly popular for offshore installations.

Contact EMAR today at www.sjt-ic.com to discuss your pulley requirements. Our engineering team provides DFM analysis and material recommendations to optimize your design for performance and cost-efficiency.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque