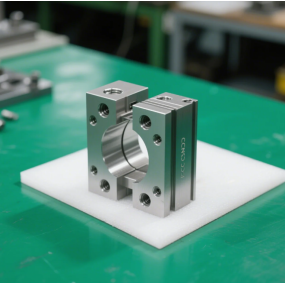

In the realm of CNC worm gear machining, precision and durability are non-negotiable. At EMAR, we specialize in manufacturing high-performance worm gears that meet the stringent demands of industries like automotive, robotics, and heavy machinery. Our advanced CNC technology ensures micron-level accuracy for smooth power transmission and extended service life.

Why Choose CNC Machining for Worm Gears?

Traditional gear manufacturing methods often struggle with the complex geometry of worm gears. Our CNC worm gear machining process overcomes these challenges through:

- 5-axis simultaneous machining for perfect tooth profiles

- Custom helix angle control (typically 5°-30°)

- Surface finishes down to Ra .8μm

- Material versatility (steel, bronze, aluminum alloys)

EMAR's Technical Capabilities

Our facility features state-of-the-art CNC gear cutting machines with:

- ±.005mm positional accuracy

- 300-800 RPM spindle speeds

- Automatic tool changers (20+ tools)

- In-process inspection systems

Quality Assurance Protocol

Every CNC-machined worm gear undergoes rigorous testing:

- 3D coordinate measurement (CMM)

- Surface hardness testing (HRC 58-62 for steel gears)

- Backlash measurement (typically .05-.15mm)

- Load testing up to 150% rated capacity

With EMAR's CNC worm gear solutions, you gain access to industry-leading manufacturing expertise backed by ISO 9001 certification. Contact our engineering team today to discuss your specific gear ratio requirements (common ratios: 5:1 to 100:1) and receive a customized quotation within 24 hours.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque