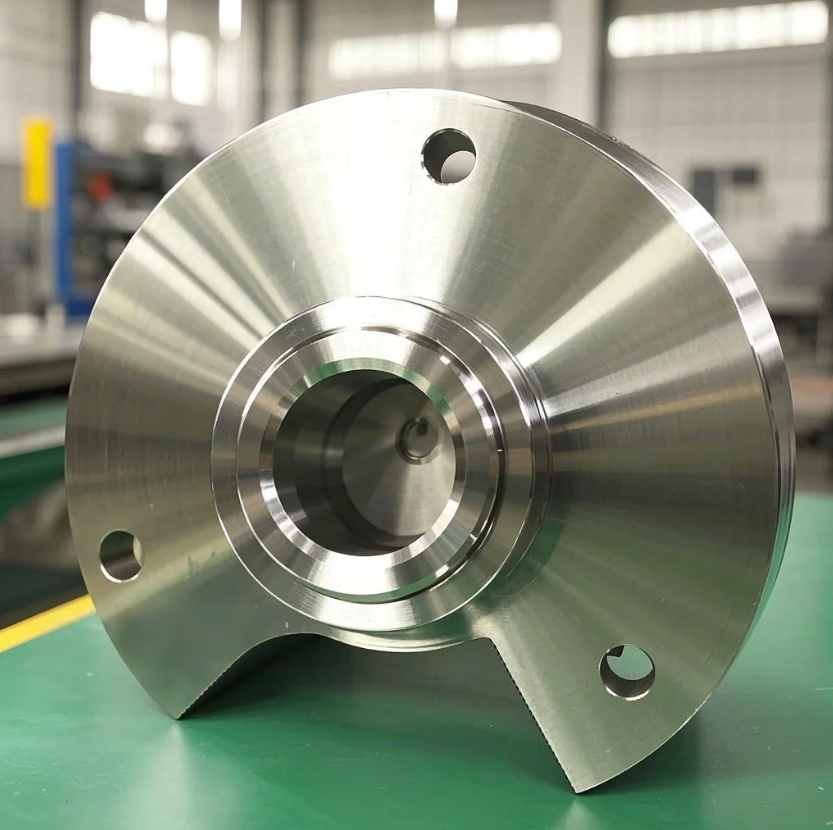

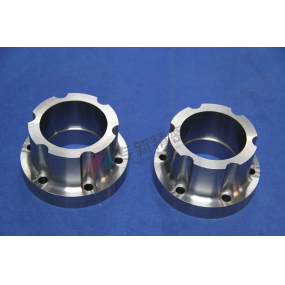

In the realm of CNC Machining camshafts, precision and durability are non-negotiable. At EMAR, we specialize in delivering high-performance camshafts tailored to meet the exacting demands of automotive, aerospace, and industrial applications. Our advanced CNC machining capabilities ensure unmatched accuracy, surface finish, and longevity for these critical components.

Why Choose CNC Machining for Camshafts?

Camshafts are the heartbeat of internal combustion engines, controlling valve timing and fuel efficiency. Traditional manufacturing methods often fall short in achieving the micron-level tolerances required for modern engines. CNC machining eliminates these limitations by leveraging computer-controlled processes to produce camshafts with:

- Precision Profiles: Consistent lobe geometry for optimal valve actuation.

- Material Versatility: Compatibility with hardened steel, alloy, or custom materials.

- Surface Integrity: Reduced friction and wear through superior finishing.

EMAR’s CNC Camshaft Machining Process

Our ISO-certified facility combines cutting-edge 5-axis CNC mills with rigorous quality checks to deliver camshafts that exceed industry standards. The process includes:

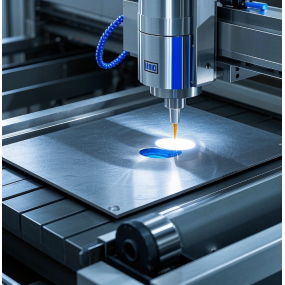

- CAD/CAM Design: Customized cam profiles based on engine specifications.

- Multi-Axis Machining: High-speed milling for complex contours.

- Heat Treatment & Finishing: Enhanced hardness and polished surfaces.

Applications Across Industries

From high-revving race engines to heavy-duty industrial machinery, EMAR’s CNC-machined camshafts are trusted by global OEMs. Our solutions cater to:

- Automotive performance upgrades

- Aerospace fuel systems

- Marine and locomotive engines

Partner with EMAR for camshafts engineered to perfection. Contact our team to discuss your project’s requirements today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque