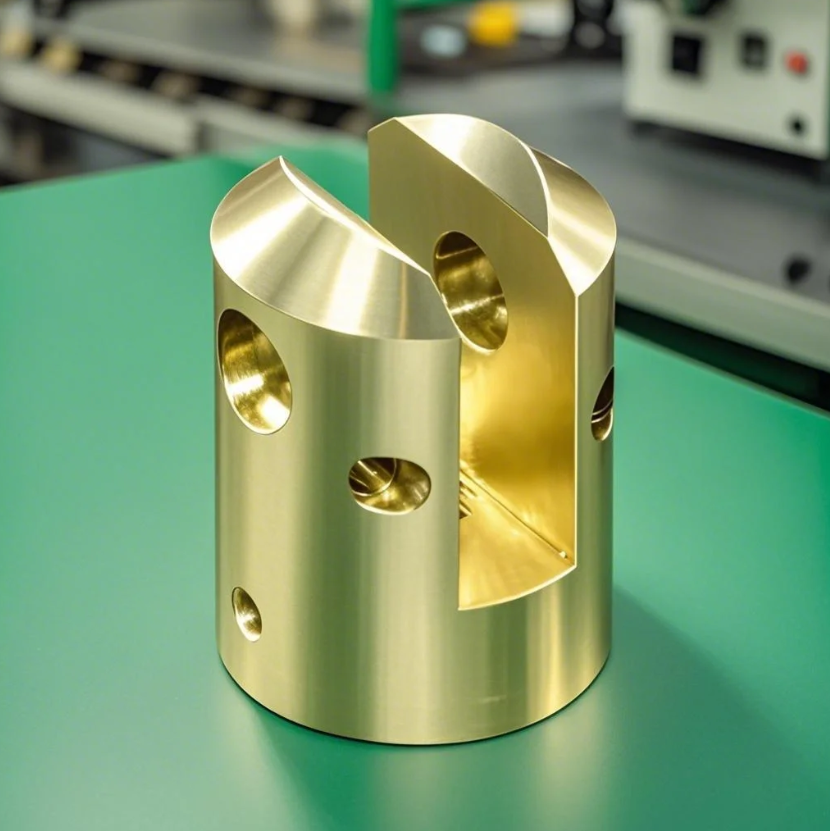

When it comes to manufacturing high-quality brass components, CNC Machining brass stands out as a reliable and efficient solution. At EMAR, we specialize in delivering precision-machined brass parts that meet the strictest industry standards. Whether you're a procurement manager, engineer, or business owner, understanding the benefits and applications of CNC-machined brass can help you make informed decisions for your projects.

Why Choose CNC Machining for Brass Components?

Brass is a popular material in various industries due to its excellent machinability, corrosion resistance, and aesthetic appeal. CNC machining enhances these properties by offering unparalleled precision and repeatability. Here's why CNC machining is ideal for brass:

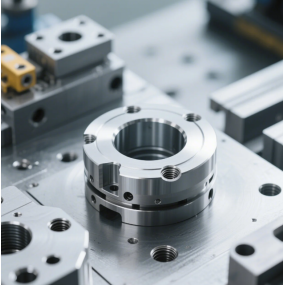

- High Precision: CNC machines can achieve tolerances as tight as ±.005mm, ensuring perfect fit and function.

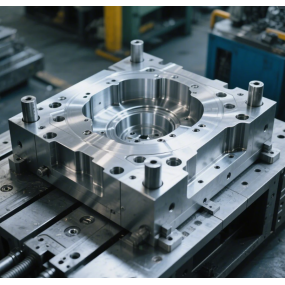

- Complex Geometries: Intricate designs and complex shapes are easily achievable with multi-axis CNC machining.

- Cost-Effective: Reduced material waste and faster production times lower overall costs.

- Superior Surface Finish: Brass components come out of the machine with smooth surfaces, often requiring minimal post-processing.

Applications of CNC Machined Brass Parts

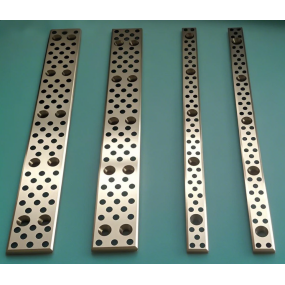

From automotive to electronics, CNC-machined brass parts play critical roles across industries. Some common applications include:

- Plumbing Fittings: Corrosion-resistant brass fittings ensure long-lasting performance in water systems.

- Electrical Connectors: Brass's excellent conductivity makes it ideal for electrical components.

- Decorative Hardware: The golden appearance of brass adds aesthetic value to architectural elements.

- Precision Instruments: Medical and scientific equipment often rely on brass components for accuracy.

EMAR's Expertise in CNC Machining Brass

At EMAR, we combine advanced CNC technology with decades of machining experience to deliver superior brass components. Our capabilities include:

- State-of-the-art 5-axis CNC machines for complex geometries

- Strict quality control measures at every production stage

- Custom solutions tailored to your specific requirements

- Competitive pricing without compromising quality

- Fast turnaround times to meet your project deadlines

Whether you need prototype development or large-scale production, our team is ready to provide the perfect CNC machining brass solution for your needs. Contact us today to discuss your project requirements and discover how EMAR can add value to your supply chain.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque