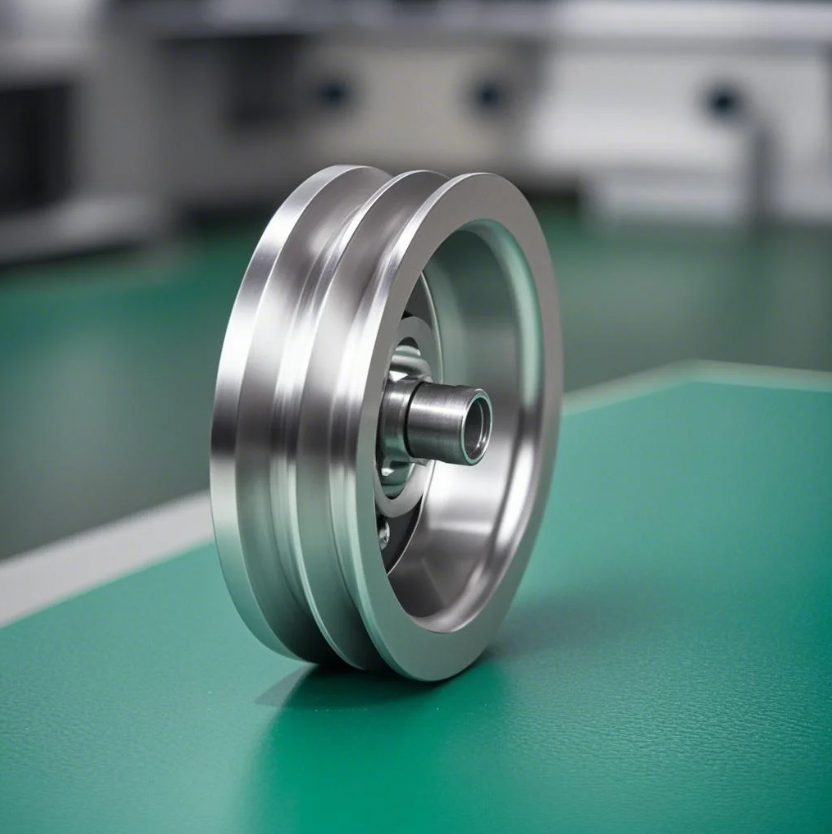

As a leading pulley CNC Machining specialist, EMAR Company delivers high-performance components for mechanical transmission systems across industries. Our ISO-certified facility combines advanced 5-axis CNC technology with aerospace-grade materials to manufacture pulleys that meet stringent tolerance requirements (±.005mm).

Why Choose CNC Machining for Pulley Manufacturing?

Traditional pulley production methods struggle to achieve the geometric complexity and surface finish requirements of modern applications. Our CNC machining process enables:

- Precision groove profiles (V-belt, timing, flat) with Ra .8μm surface finish

- True concentricity between bore and outer diameter

- Custom lightweight designs with optimized wall thickness

- Material versatility (aluminum 6061-T6, stainless 303/304, brass C360)

EMAR's Technical Capabilities in Pulley Production

Our 15,000 sqm facility features Mori Seiki NVX500 CNC mills and Okuma MULTUS U300 turning centers capable of producing pulleys from 10mm to 800mm diameter. All components undergo CMM inspection (Zeiss CONTURA G2) with full traceability documentation.

Industry-Specific Solutions

We engineer CNC machined pulleys for:

- Automotive: Serpentine belt systems with harmonic vibration analysis

- Robotics: High-ratio timing pulleys with ceramic coating options

- HVAC: Corrosion-resistant aluminum sheaves for blower assemblies

- Agricultural: Heavy-duty pulleys with hard-anodized surfaces

With 72-hour rapid prototyping and annual production capacity exceeding 500,000 precision parts, EMAR serves global clients through our Shanghai headquarters and international logistics network. Request your custom pulley machining quote today at www.sjt-ic.com.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque