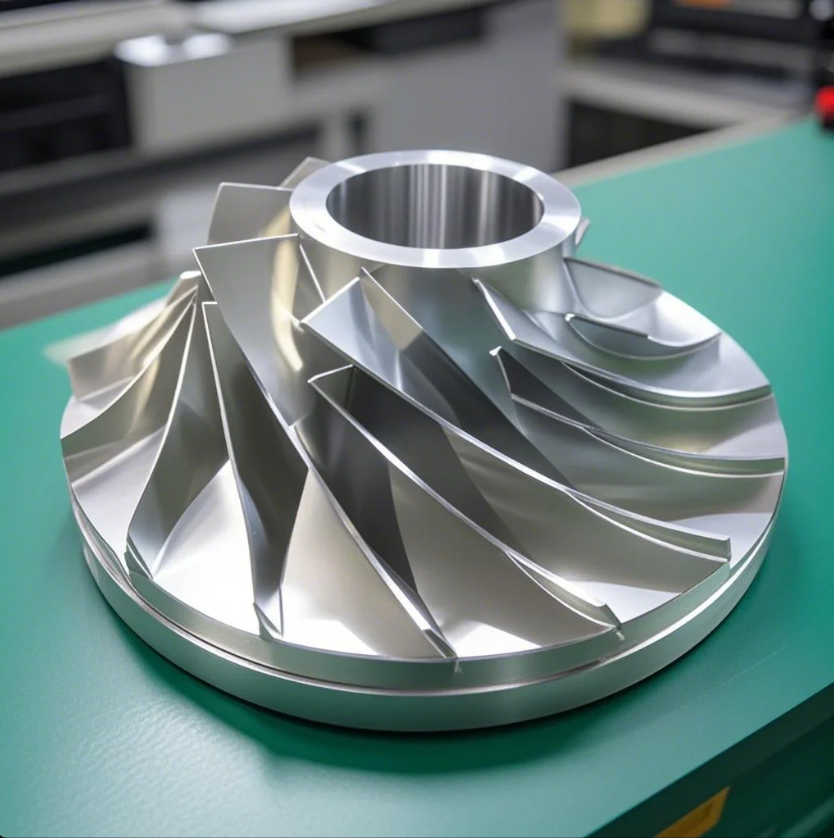

In industries requiring high-efficiency fluid dynamics, such as aerospace, automotive, and energy sectors, CNC impeller machining stands as a critical manufacturing process. EMAR Company specializes in delivering precision-machined impellers that meet stringent industry standards.

What is CNC Impeller Machining?

CNC impeller machining refers to the computer-controlled manufacturing of turbine impellers with complex geometries. Our 5-axis CNC machines achieve tolerances within ±.01mm, ensuring perfect balance and hydrodynamic efficiency.

Key Advantages of Our CNC Impeller Machining Services

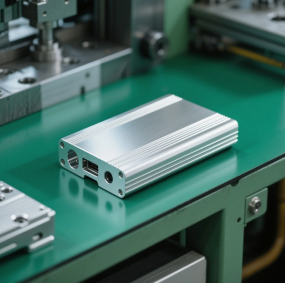

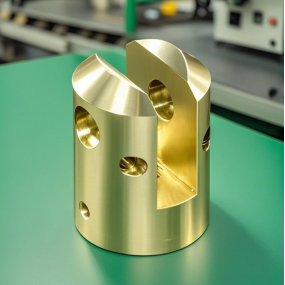

1. Material Expertise: We machine aluminum, titanium, stainless steel, and high-performance alloys

2. Surface Finish: Ra .4μm achievable for reduced friction losses

3. Quality Assurance: CMM inspection and dynamic balancing testing included

Why Choose EMAR for Your Impeller Machining Needs?

With 15+ years in CNC Machining, we offer:

- Prototype to mass production capabilities

- DFM (Design for Manufacturing) support

- ISO 9001-certified processes

- Fast turnaround with 24/7 production capacity

Contact our engineering team at EMAR Company to discuss your specific impeller requirements and receive a free project analysis.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque