As a professional CNC turning service provider, EMAR understands that pricing transparency is a top concern for procurement managers and engineers. This article breaks down the key factors influencing CNC Turning Machining Quotations and how our company delivers competitive value.

What Determines CNC Turning Service Pricing?

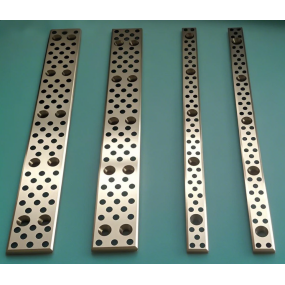

1. Material Costs: Aluminum, stainless steel, and titanium have vastly different raw material prices.

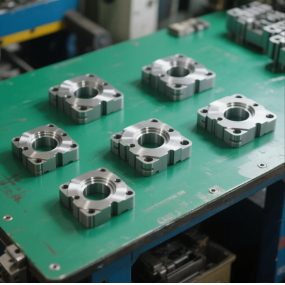

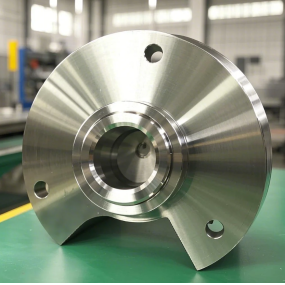

2. Part Complexity: Tight tolerances (e.g., ±.005mm) and intricate geometries increase machining time.

3. Batch Size: Volume discounts apply for orders exceeding 500+ parts.

4. Secondary Operations: Additional processes like anodizing or heat treatment affect final costs.

EMAR's Competitive Advantages in CNC Turning

Our ISO 9001-certified facility in [Location] features:

• 32-axis live tooling lathes for complex parts

• In-house material testing lab for quality assurance

• ERP system providing real-time CNC turning service quotes within 4 hours

Cost-Saving Strategies We Recommend

1. Design for Manufacturability: Our engineers offer free DFM analysis to optimize your CAD files.

2. Standardized Tooling: Using common tool sizes reduces setup costs by 15-20%.

3. Annual Volume Commitments: Contract customers receive preferential pricing tiers.

Request an instant quote through our online portal at www.sjt-ic.com or contact our technical sales team for project-specific consultations.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque