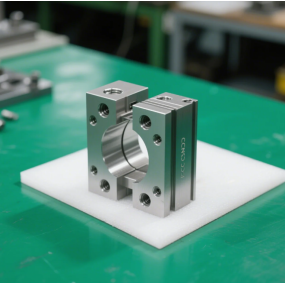

In today's competitive manufacturing landscape, CNC product mass production has become a cornerstone for industries requiring high-volume output without compromising precision. As a leading CNC Machining service provider, EMAR specializes in delivering scalable solutions that meet the stringent demands of aerospace, automotive, electronics, and medical sectors.

Why Choose CNC for Mass Production?

CNC (Computer Numerical Control) machining offers unparalleled advantages for large-scale manufacturing. With EMAR's advanced multi-axis CNC centers and automated tool changers, we achieve:

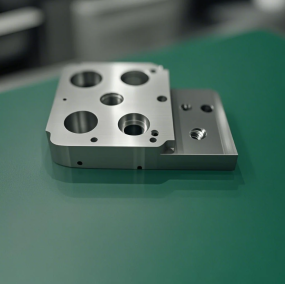

- Consistent precision (±.005mm tolerance)

- 24/7 production capability with minimal supervision

- Seamless replication of complex geometries

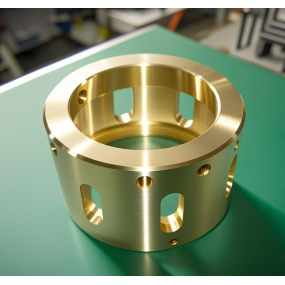

- Material versatility (metals, plastics, composites)

EMAR's Mass Production Capabilities

Our CNC product mass production workflow integrates cutting-edge technology with lean manufacturing principles:

- Dedicated Production Cells: High-speed machining centers with pallet changers for uninterrupted operation

- In-line Quality Control: Automated CMM inspection every 500th part

- Material Management: Just-in-time inventory with certified material traceability

- Post-processing Integration: Anodizing, plating, and heat treatment in-house

Cost Optimization Strategies

For buyers focused on CNC product mass production economics, EMAR implements:

- Toolpath optimization reducing cycle times by 15-30%

- Multi-fixture setups enabling parallel processing

- Volume-based pricing models with MOQs as low as 5,000 units

- DFM (Design for Manufacturing) consultations to reduce per-unit costs

With ISO 9001:2015 certification and a 98.7% on-time delivery rate, EMAR stands as your trusted partner for high-volume CNC machining. Our engineering team works closely with clients to develop production solutions that balance speed, quality, and cost-effectiveness.

Explore our full capabilities at www.sjt-ic.com or request a project consultation today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque