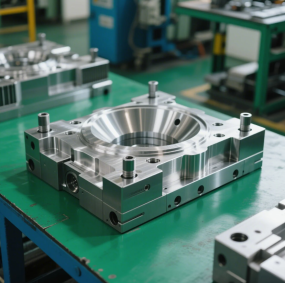

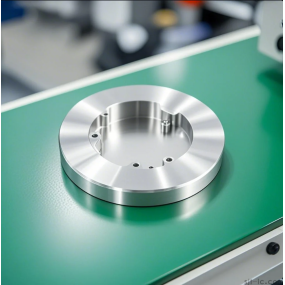

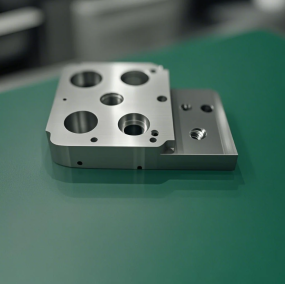

As a leading provider of CNC Machining services, EMAR specializes in delivering high-quality, precision-engineered components for industries ranging from aerospace to medical devices. Our advanced manufacturing capabilities ensure exceptional accuracy, efficiency, and consistency for your projects.

Why Choose CNC Machining?

CNC machining offers numerous advantages over traditional manufacturing methods. The computer-controlled process eliminates human error while enabling complex geometries and tight tolerances (±.001"). Our 5-axis machines can produce intricate parts from over 50 engineering-grade materials, including aluminum, titanium, and plastics.

Key Benefits of Our CNC Services

1. Superior Precision: Achieve micron-level accuracy for mission-critical components

2. Rapid Prototyping: Reduce development time with fast turnaround capabilities

3. Cost Efficiency: Optimize production with automated, waste-minimizing processes

4. Material Versatility: Machine virtually any machinable material to specifications

5. Scalability: Seamlessly transition from prototypes to full production runs

Industry-Specific Solutions

Our CNC machining expertise serves diverse sectors:

- Aerospace: FAA-compliant aircraft components

- Medical: FDA-approved surgical instruments

- Automotive: High-performance engine parts

- Electronics: Precision enclosures and heat sinks

EMAR's Quality Assurance

Every component undergoes rigorous inspection using CMMs and optical comparators. We maintain ISO 9001 certification and provide full material traceability with certified test reports. Our engineering team works closely with clients to optimize designs for manufacturability and cost-effectiveness.

Discover how EMAR's CNC machining solutions can enhance your production. Visit www.sjt-ic.com to request a free project evaluation and quote today.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque