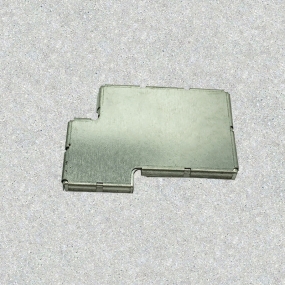

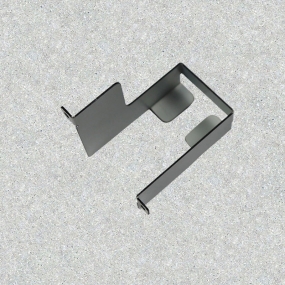

Water tank processing and Sheet Metal Processing are the key technologies that sheet metal technicians need to grasp, and they are also important processes for forming sheet metal products. Sheet metal processing includes traditional methods and process parameters such as cutting, punching, and bending forming, as well as various cold stamping die structures and process parameters, equipment working principles and operation methods, and new stamping technologies and processes. The processing of metal sheet parts is called sheet metal processing.

Sheet metal processing is called sheet metal processing. For example, using sheet metal to make chimneys, iron drums, oil tanks and pots, ventilation ducts, elbow heads, round corners, funnel-shaped structures, etc. The main processes include cutting, bending edges, bending forming, welding, riveting, etc., which require a certain amount of geometric knowledge. Sheet metal parts are thin metal parts that can be processed through stamping, bending, stretching, and other methods. A general definition is parts with constant thickness during the processing. Correspondingly, there are castings, forged parts, machined parts, etc.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque