Characteristics of stainless steel aviation parts processing and aviation parts manufacturing industry

The stainless steel aviation parts processing and aviation parts manufacturing industry emerged in the 1960s. With the globalization of the economy, by the 1990s, the industry had become relatively mature. As the business scope continued to expand, its industry characteristics gradually emerged. Below, we summarize its industry characteristics:

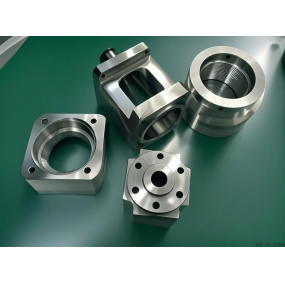

1. Wide range of component types and high degree of customization

The degree of component customization is relatively high, and it can be customized separately for different parts of different models of aircraft. It should be noted that there are many components in an aircraft, and the requirements for design, material selection, and production processes of each component are different. Therefore, the production cycle and production investment of this industry are relatively large.

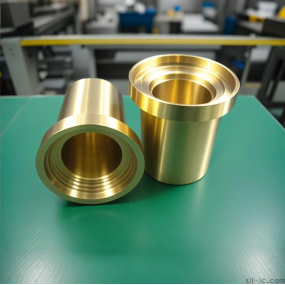

2. High industry barriers

Because airplanes are not tools for mass production, there is a high demand for the quality of their components, which require them to have high safety, reliability, and stability. Manufacturers must obtain corresponding qualifications and certifications before they can be put into production, so the industry barrier is relatively high.

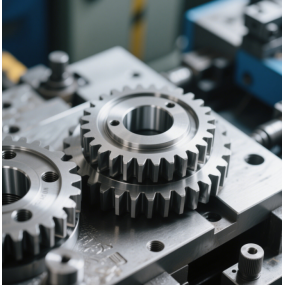

3. Implement a collaborative and supporting production cooperation model

There is a high degree of linkage between general component manufacturers and aircraft engine manufacturers, and aircraft engine manufacturers often evaluate the production quality of component manufacturers through contractual agreements and assessment methods. Manage production time and progress, and even the finished products produced by component manufacturers need to be handed over to the aircraft host factory for quality inspection first.

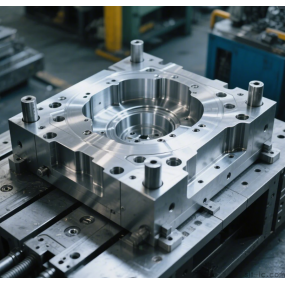

4. The marketization level of military component manufacturing is relatively low

At present, there are relatively few domestic manufacturers of military components, and due to the high threshold of idleness, there are fewer private manufacturers participating in market competition. Therefore, the degree of marketization is relatively low and the market competitiveness is not strong.

The aviation parts manufacturing industry still needs policy support and efforts from industry insiders to develop towards diversification.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque