Machine tool cover

Machine tool protective cover is used to protect the machine tool. It can protect the surface of the machine tool from external corrosion and damage. There are many types, including organ protective cover, steel plate protective cover, which are used on the guide rail. There are also screw protective covers used on the lead screw, including circular, square, and polygonal. The methods of these methods are different. There are steel wire support type, sewing type, rolling shutter type protective cover, and armor protective cover.

Machine tool protective covers can be divided into internal protection and external protection. Below is a brief introduction to the classification of internal protection. Steel plates and stainless steel protective covers have the characteristics of good sealing, resistance to iron filings, coolant, tool accidents, durability, and beautiful appearance. It is used to protect the machine tool. It can protect the surface of the machine tool from external corrosion and damage. There are many types of it. There are: organ protective cover, steel plate protective cover, which are used on the guide rail. There are also screw protective covers used on the lead screw, including circular, square, and polygonal. These methods are different. There are steel wire support type, sewing type, rolling shutter type protective cover, and armor protective cover.

Rolling shutter type protective cover

The automatic retractable protective belt made of stainless steel material for the shell is composed of the shell, spring shaft, and fiber

Composed of protective curtains and other materials. The outer shell is made of stainless steel or cold rail plate and has undergone surface anti-corrosion treatment. The internal structure is assembled from heat-treated steel strips. The structure of this product is tight, reasonable, and noise free, suitable for use in machine tools with small space, large stroke, and fast movement.

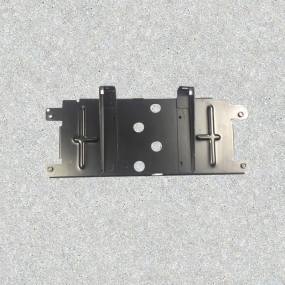

Armor type

The idea of armor skin cavity comes from installing a high-performance, lightweight, but flexible steel sheet protective layer on top of the traditional skin cavity. And this steel plate, with a shape very similar to the armor on ancient warrior's war clothes, is named Armor Plate.

The fixing method of armor plates can be divided into three basic forms. Different product models and names have emerged from these three basic fixing methods. FASTAF/FASTAC models use fixed armor plates. FASTAM/FASLAP uses active armor plates to continuously improve the performance of this type of skin cavity through user made improvements.

The fully protected armor skin cavity (FASTAC) has been newly developed. It is developed based on the fixed armor skin cavity (FASTAF), where each armor piece covers the top and sides of the skin cavity, forming a closed protective surface.

Organ style protective cover:

Its smooth surface, regular shape, and beautiful appearance add infinite colors to the overall shape of the machine tool. So, while providing practical protection for your machine tool, it also adds more visibility to the machine tool

The aesthetic appeal of the organ style machine tool protective cover enhances the overall value of the machine tool. The organ style protective cover adopts advanced German technology, with German nylon cloth on the outside and PVC board support on the inside. It is resistant to oil, corrosion, hard impact without deformation, has a long service life, good sealing, smooth walking, and is sturdy and durable. It is mainly used to protect various confidential mechanical components and extend the service life of important mechanical parts and machinery.

This type of shield has the characteristics of not being afraid of stepping on, not deforming due to hard object impact, long service life, good sealing, and lightweight operation

The shield has a long travel and low compression, with a length ratio of 1:10

This folding cover is a form that can compensate for problems that cannot be solved by various covers. This type of shield holds a leading position in the world.

This product uses specialized materials that are resistant to coolant, oil, grinding wheel foam, and iron shavings, among others;

The advantages of long travel and low compression of protective covers;

The wind box speed of the protective cover can reach 200m/min

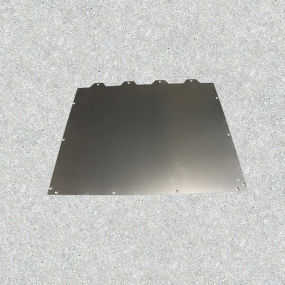

Characteristics of steel plate protective cover:

Steel telescopic guide rail protective cover is a traditional form of protection for machine tools. Steel telescopic guide rail protective covers are widely used in this field, providing effective protection against the entry of chips and other sharp objects

The protective cover can effectively reduce the infiltration of coolant through certain structural measures and suitable scraper plates. Our steel telescopic guide rail protective cover can meet the constantly increasing requirements of modern machine tools in terms of high technology, correct installation position, and high operating speed.

Suitable for high-speed motion machine tool guide rail protection that is both smooth and free of vibration and noise. (Can operate normally at a speed of 80m/min)

Each section of the protective plate is simultaneously pulled apart and retracted in parallel, allowing for smooth operation.

It will not cause the protective plate to detach, and there will be a sound of impact, which is both aesthetically pleasing and improves the service life of the protective plate.

On the basis of the original sealing strip, a layer of stainless steel cover plate was added to prevent iron filings from burning the sealing strip at high temperatures and damaging the guide rail by rubbing it into the track surface.

This device not only protects the service life of the protective plate, but more importantly, ensures the precision of the machine tool

Features of retractable screw guard:

Function of protective cover: It can be used to protect the screw, rod, column, spindle, and other circular rotating columns of the screw protective cover. Can be used horizontally or vertically. When using horizontally, it is recommended to use plastic or aluminum support rings to maintain a certain uniform distance between the inner cavity of the shield and the screw rod, in order to extend the service life. When the stretching length is large, metal rings can be added at each compromise to improve the stability of the shield. Metal flanges are usually used for connecting or fixing ends, but sleeve type can also be chosen.

Characteristics of Armored Machine Tool Protective Cover:

Each layer of it can withstand strong vibrations without deformation, and should be protected by armor on the bellows to maintain its original state at a high temperature of 900 ℃. They support each other and act as barriers to the penetration of small fragments.

Press the expansion piece on the protective cover grid

Necessary conditions for small space

A reliable protective layer that can withstand a large amount of dust, sand, and iron shavings

The expansion plate is made of aluminum alloy and stainless steel plate

There is no bonding relationship

English

English » » »

» » »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque