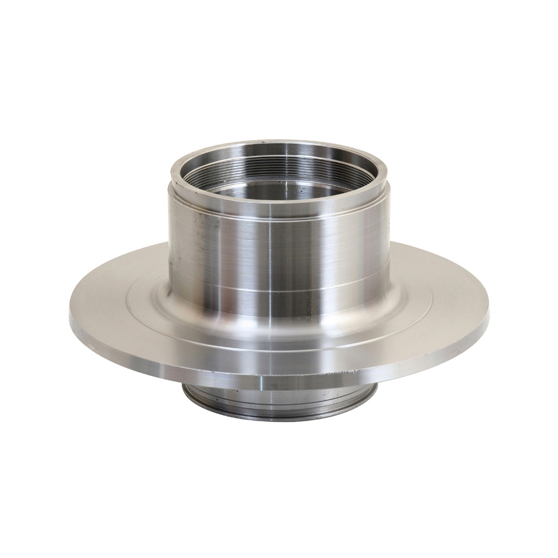

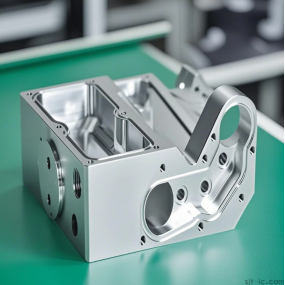

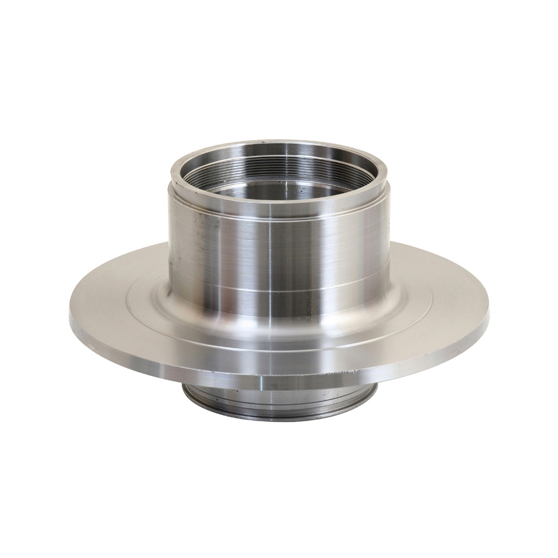

The four major advantages of a five axis CNC Machining center are that it adopts a vertical and horizontal swing structure and can be continuously flipped. The turntable adopts a worm drive structure with high transmission torque, suitable for low-speed and heavy-duty cutting; Alternatively, torque motor drive can be selected, with fast dynamic response, no reverse clearance, and no transmission mechanical wear, suitable for high-speed, high-precision light load cutting. The machine tool used is usually referred to as a five axis machine tool or a five axis machining center. Five axis CNC machining is commonly used in the aerospace industry to process body parts, turbine parts, and impellers with free-form surfaces. When describing the motion of a CNC machine tool, use a right Cartesian coordinate system; The coordinate axis parallel to the main axis is defined as the Z-axis, and the rotation coordinates of the winding x, y, and z-axis are A, B, and C, respectively. Usually, five axis linkage refers to linear interpolation motion of any 5 coordinates, including x, y, z, A, B, and C. 1. Greatly shortened processing time: Due to the automatic breakage of the drill bit shape used by global CNC deep hole drilling machines and the continuous discharge of high-pressure chip oil, there is no need to exit the drill bit midway and clean the chips. The processing speed of the processing hole can be 5-6 times faster than that of the Fried Dough Twists drill. 2. Edge grinding of cutting tools: Even without a specialized tool grinding machine, it is easy to grind again. (When proficient, you can grind it by hand). Deep hole drilling can be ground 50-60 times. Therefore, the service life of deep hole drill bits is longer. Compared with Fried Dough Twists drills, the cost of cutting tools is not high. 3. Processing materials with high hardness: Due to the fact that the deep hole drill bits of Global CNC deep hole drills (three-axis deep hole drills, five axis deep hole drills) are made of hard alloy, they can process materials with a hardness of HRC40. 4. The five axis deep hole drill adopts an integrated design: the slider is hinged on the overall slide table through the central axis, and the servo motor drives the slider to rotate through the reducer. The rotation deviation device installed on the central axis is used to control the rotation angle, so that the spindle can be tilted at a certain angle for tilt processing, positioning, and stiffness strength.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque