In the field of machinery manufacturing, CNC Machining the transmission worm gear is a high-precision and high-complexity process. As the core component of the transmission system, the processing quality of the transmission worm gear directly affects the operating efficiency and life of the equipment. So, what is the specific way of CNC machining the transmission worm gear? What are the key steps in the processing process? This article will answer you in detail.

The core method of CNC machining transmission worm gears CNC machining transmission worm gears mainly uses numerical control machine tools for high-precision cutting and forming. Its core methods include:

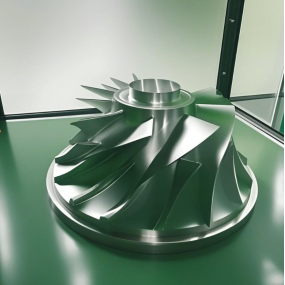

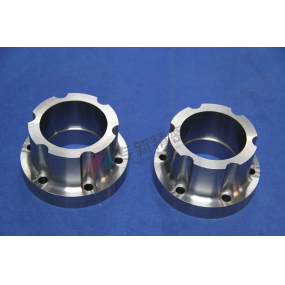

Numerical control turning: The rough machining of the worm gear is carried out by numerical control lathe to ensure the dimensional accuracy and surface finish. Numerical control milling: The worm gear tooth shape is finished by numerical control milling machine to ensure the tooth shape accuracy and meshing performance. Heat treatment: The hardness and wear resistance of the worm gear are improved by quenching, tempering and other processes. Detailed process of transmission worm gear processing The processing process of transmission worm gear is divided into the following key steps:

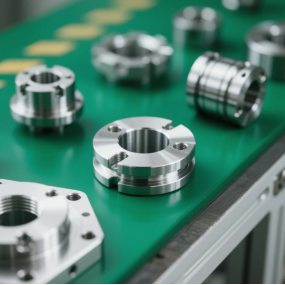

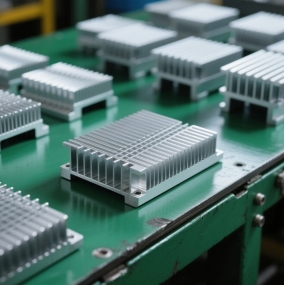

Material selection: Choose the appropriate material according to the use scenario, such as alloy steel, stainless steel or copper alloy. Blank processing: Prepare the worm gear blank by forging or casting process to ensure the uniform internal structure of the material. CNC roughing: Use numerical control lathe to carry out preliminary processing of the blank to remove excess material. CNC finishing: Perform high-precision processing of the worm gear tooth shape by numerical control milling machine to ensure that the tooth shape error is controlled at the micron level. Heat treatment: Perform heat treatment on the finished worm gear to improve its hardness and wear resistance. Surface treatment: Improve the surface quality and corrosion resistance of the worm gear by polishing, plating and other processes. Quality inspection: Use coordinate measuring machine and other equipment to test the size and shape tolerance of the worm gear to ensure that the product meets the design requirements. Advantages of EMAR Company As a professional machining service provider, EMAR Company has the following advantages in the field of CNC machining transmission worm gears:

Advanced Equipment: Equipped with multiple high-precision numerical control machine tools to ensure machining accuracy and efficiency. Professional Team: With experienced engineers and technicians, able to provide customized solutions for customers. Strict Quality Inspection: Adopt international standard quality inspection system to ensure that every product meets customer requirements. Fast Delivery: Optimize the production process, shorten the delivery cycle and meet the urgent needs of customers. If you need high-quality CNC machining transmission worm gear services, welcome to visit the official website https://www.sjt-ic.com EMAR company for more product and service details.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque