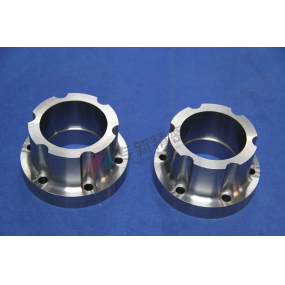

In the field of machinery manufacturing, CNC Machining pulleys is a high-precision and high-efficiency processing method, which is widely used in automobiles, industrial equipment and other fields. This article will provide a detailed explanation of the processing method and process flow of pulleys to help you better understand this technology.

CNC machining pulley processing method CNC machining pulley is mainly realized by numerical control machine tool, its core advantage is high precision and automation. The following are common processing methods:

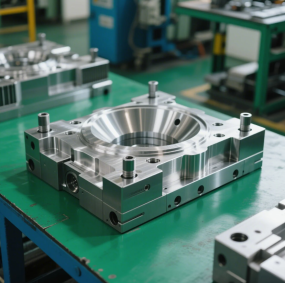

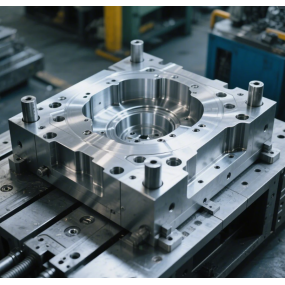

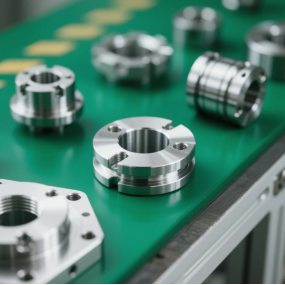

Turning processing: Precision machining of the outer circle, inner hole and other parts of the pulley by numerical control lathe. Milling processing: It is used to process the groove, tooth shape and other complex structures of the pulley. Grinding processing: It is used to improve the surface finish and dimensional accuracy of the pulley. Detailed process of pulley processing The processing flow of the pulley usually includes the following steps:

Material selection: Select the appropriate material according to the use scenario, such as aluminum alloy, steel, etc. Roughing: Preliminary molding of the blank by turning or milling. Finishing: Fine machining of the key parts of the pulley using high-precision numerical control machine tools. Surface treatment: Improve the durability and aesthetics of the pulley through polishing, electroplating and other processes. Quality inspection: Size and performance testing of the finished product using equipment such as three-coordinate measuring machine. Advantages of EMAR Company As a professional machining service provider, EMAR Company has rich experience and technical advantages in the field of CNC machining pulleys:

Advanced numerical control equipment to ensure machining accuracy and efficiency. Strict quality control system to ensure that every product meets customer requirements. Provide customized services to meet the special needs of different industries. If you need high-quality customized parts for pulleys, please visit EMAR‘s official website for more information, or contact our professional team directly for solutions.

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque