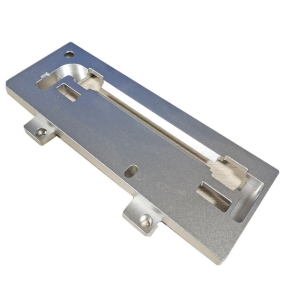

The five axis CNC Machining center is suitable for manufacturing and processing body parts, fan impellers, and other components with free-form surfaces. We can find that products suitable for manufacturing and processing with five axis machining centers have a high degree of curvature, and it is difficult to manufacture and process them according to the characteristics of one clamping. Therefore, five axis machine tools can carry out manufacturing and processing on different sides of the product without changing the orientation of the product on the machine tool, improving the manufacturing and processing power of prismatic parts.

Bost ardatz CNC makina-zentro batek hiru ardatz mugitzen ditu X, Y eta Z, eta bi ardatz biratzen ditu. Hiru ardatz-makina tradizionalarekin batera, bost ardatz-konektatzeko makina-konektatzeko zentroaren bost ardatz-konektatzeko teknologia konektatzeko aukera ematen du tresna hori bost gradu askatasunaren posizioan egotea, hiru-dimentsio geometria nahastuekin produktuak sortzen dituenean. Eremu profesionalean lagun askok galdera bat dute bost ardatz makina-zentroa ulertzeko, hiru ardatz makina-zentroan oinarrituta dagoela eta bi ardatz biratzeko. Bi biraketaren ardatz hauek lehenengo aldaketa-tresna mugitzen dute kokaleku batean, eta gero mugitu eta prozesatzen dute X, Y eta Z ardatz bidez.

Egiaztapen eta prozesatzeko metodo antzekoak uste dute laugarren eta bosgarren ardatzak tresnaren norabidea orientazio stabil batean zehazteko erabiltzen direla, makina-prozesuaren bitartean jarraitzeko baino. Horregatik, hau ez da egiazko bost ardatz-konektatzeko teknologia. 3+2 ardatz-makina zentro batek makina-zentro arruntak ezin dituzten prozesuak erabil dezake, baina hau ez da egiazko bost ardatz-makina-zentroa ere.

A real five axis machining center has a tool point following function, which can ensure that the cutting point of the tool and the surface of the part touch without changing the basic parameters, avoiding the occurrence of cutting pits. During the entire process of movement, the direction of the tool can be optimized, while the tool moves in a straight line. In this way, suitable cutting conditions can be maintained throughout all pathways. Five axis machining center is currently a very useful equipment for manufacturing and processing heterojunctions, boxes, and cluttered cavities. It has a significant impact on precision instruments, automotive equipment, high-precision medical equipment, and other fields.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole