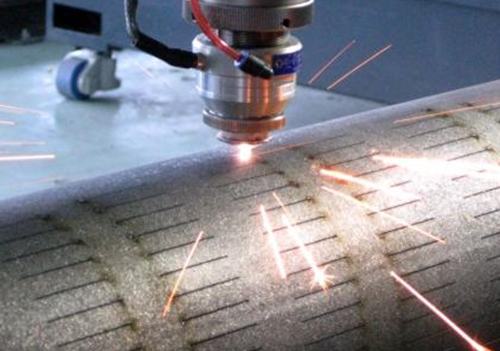

Laser cutting machines have very good cutting effects, with obvious advantages in flexible processing compared to traditional cutting, saving time and manpower, and being efficient and high-precision. Due to the increasingly widespread use of metal laser cutting machines, they are being applied in industries such as Sheet Metal Processing, aviation, electronics, electrical appliances, and kitchenware. Below, the editor will introduce how to use a laser cutting machine to achieve good cutting results.

1. O sistema de refrigeración debe estar embaixado e o tanque de auga e as vías de auga deben limpar regularmente. O punto de control da temperatura do tanque de auga de control da temperatura de refrigeración debe ser xusto, caso contrario causará danos fáceis ao tubo láser, diminuirá a potencia de condensación, desmantelar a cabeza de auga fría do tubo, cortar moito a vida de servizo e ás veces fallar, resultando en substitución continua do tubo.

2. O punto de soporte da instalación do tubo láser da máquina de corte láser debería ser razoábel, e o punto de soporte debería estar a 1/4 da lonxitude total do tubo láser, de outro xeito causará que o modo spot do tubo láser se deteriore, e algúns traballos durante un período de tempo causarán que o punto se converta en varios puntos, resultando nunha diminución da potencia láser que non pode satisfacer os requisitos, causando a substitución continua do tubo.

3. Water protection should be checked and cleaned regularly. Cooling water often cannot flush the water protection float switch or the water protection float switch does not reset. Short circuiting methods should not be used to solve urgent problems.

4. O dispositivo de sacación debe ser comprobado e limpado regularmente e os canais de ventilación deben ser limpados con precisión Caso contrario, non se pode descargar moito fume e polvo, contaminando gravemente e rapidamente as lentes e os tubos láser, causando unha oxidación fácil de diversos componentes mecánicos e electrónicos e un mal contacto.

5. Focus lens and reflector inspection, after working for a while, the frame will have a fever, and the surface of the lens will change color and rust; Peeling and cracking are all objects that need to be replaced, especially for many customers who use large air pumps and compressors, which quickly accumulate water on the focusing lens. Therefore, it is necessary to check the cleanliness and quality of the lens optical path system on time.

6. The working environment of the laser cutting machine should not be too harsh. If the ambient temperature is above 30 degrees and below 18 degrees, there will be too much dust and severe air pollution, which will severely damage the machine and increase the failure rate; Electrical components are prone to problems in humid environments.

O contido do artigo é fonte de internet. Se ten preguntas, contacte comigo para borralo!

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque