A punch press is a stamping type press machine. In production, the stamping process has the power to save materials compared to traditional mechanical processing, and has high efficiency. It also does not require high operator skills and can produce products that cannot be reached by mechanical processing through various mold applications. Therefore, its use in stamping factories is becoming increasingly widespread. Punching machines are widely used in electronics, communications, computers, household appliances, furniture, transportation, hardware components, and other stamping and forming industries.

Strojevi za udaranje igraju mnoge uloge u obradi aparatne opreme:

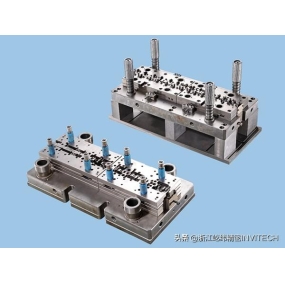

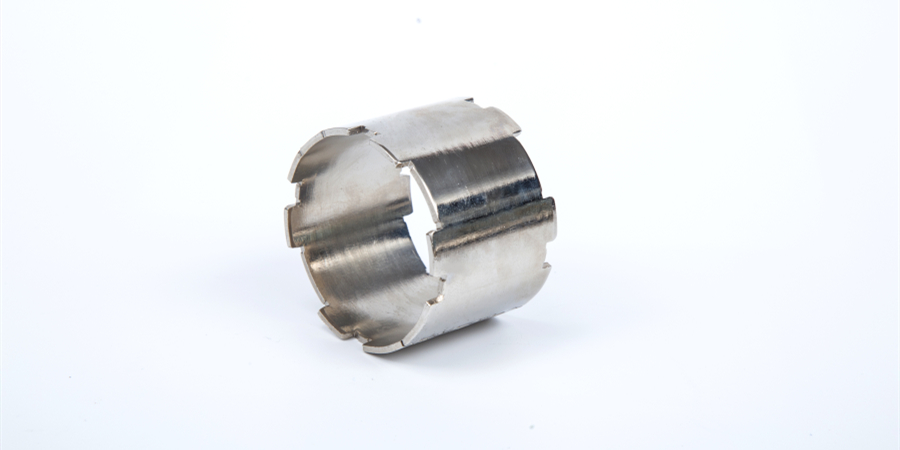

1. Punching, thick sheet punching, and punching production are mainly aimed at sheet metal. They can pass through molds, make cutting, punching, forming, deep drawing, trimming, precision punching, shaping, riveting, and extrusion parts, etc. They can process parts with large scales and complex shapes. Five Metal Stamping has high strength and rigidity.

2. Formiranje, kao što su željezne ploče, čaše, kabinete, ploče itd., zahtijeva manje materijalne potrošnje za obrađivanje metalnih štampanja u fabrikama štampanja, a troškovi dijelova štampanja metala također su relativno niske.

3. Trimming i formiranje se može primjenjivati na neobične metalne površine. Tijekom štampanja metala, mold osigurava stabilnost skale, preciznost oblika i kvalitetu dijelova štampanja metala.

4. Povezivanje dva metalnog objekta zajedno potroši manje materijala i ne zahtijeva drugu opremu za zagrijanje. To je također metod obrade materijalne uštede i energetske uštede. Troškovi metalnih članaka su niske, čineći ga prikladnom za veliku proizvodnju i primjenu.

Ovaj članak je iz EMAR Mold Co., Ltd. Za više informacija o EMAR-u, kliknite na www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque