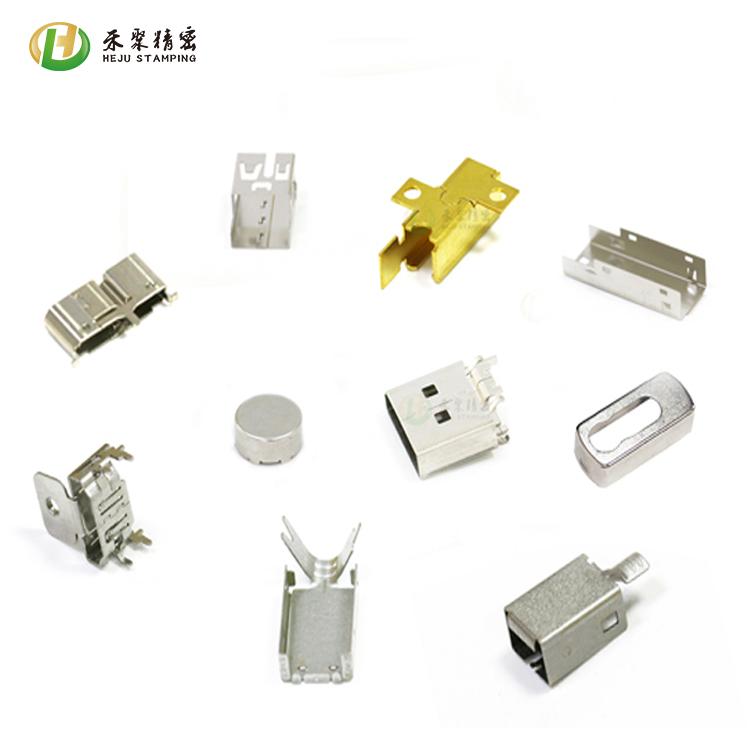

Sheet metal is one of the three elements of stamping processing. Enpòtans pou elektronik hardware en stamping pati ak elektronik stamping pati enplike pwopriyete fizik tankou dud materyèl, tansil fòs, ak tout fòs efè. Stamping forming process involves stamping cutting, stamping bending, stamping stretching and other related processes. Nan anpil miltip materyèl metal, chak materyèl gen pwòp karakteristik li, Et designers jeneralman juze si pwosesis sa a bon pou materyèl sa ki baze sou karakteristik li.

Lè frèt ruvant kabòn an ti wòch ak strip pou elektronik materyèl en pati ak elektronik stamping materyèl, yo sont suitable pou pwodwi ak pi ba stamping traiter degre, tankou ranpli, plon, etc. Steel is suitable for stamping and stretching requirements, as well as for stamping parts with repeated stamping or highly formed SPCE: the tensile performance is higher than SPCD, and the surface needs to be electroplated (this material is used less frequently).

SECC material is equipped with a galvanized layer, which has good anti-corrosion performance. Jeneralman te itilize pou echantiyon apati pati de elektronik hardware en pati.

Stainless steel has physical properties such as high hardness, high strength, corrosion resistance, welding performance, and antibacterial properties. Selekte klas materyèl byen konvenab selon sa a fonksyonal nesesè de tout pati echantiyon an pandan echantiyon pwosesis.

Stainless steel 301: Li gen yon relativement faible renmen chromium ak pòv korozyon rezistans, men materyèl la ka sèvi anwo nan syèl la a tout pouvwa tensile ak pèd apre chalè tretman, ak gen bon elastik pwopriyete. Li exposés evidan travay di fenomèn pandan deformation Et se itilize nan plizyè sitiyasyon ki bezwen fòs anwo nan syèl la.

Stainless steel 304: Kontni kabòn a, tout pouvwa, Et durus sont tout pi ba pase SUS301. But the material added has strong corrosion resistance. Wo de forte ak dikèv kapab wè nan tretman chalè. Wid te itilize nan pwodwi ekilè ak composants ki bezwen bon konplètman (korozyon resistans ak qui).

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Spanish Basque

Spanish Basque