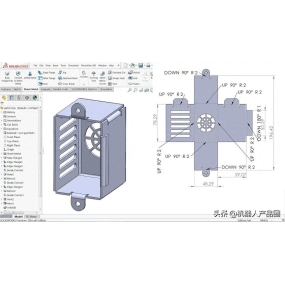

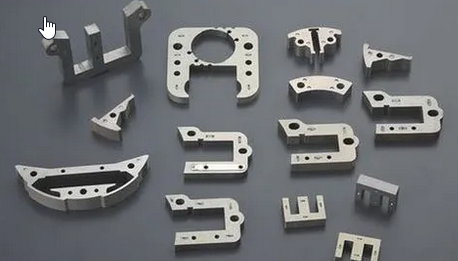

Hardware processing is the process of processing raw materials (stainless steel, copper, aluminum, iron...) into various parts using lathes, milling machines, drilling machines, polishing machines, and other machinery according to customer drawings or samples, such as screws, motor shafts, model car parts, fishing gear accessories, speaker product casings, mobile power supply casings, etc.

Afè pwogramasyon de pati materyèl:

1. Spray tablo proténsif: Fabrik Hardware ki itilize spray penti proténsif pou pwodwi gwo pwodwi materyèl, ki ede pwotensif en rous composants hardwaryè, tankou chak jou nesesès, elektrik casings, handicrafts, etc.

2. Electroplating: Electroplating se tou a ki pi komen pwosesis teknoloji nan pwosesis hardware. Pa itilize modèn teknoloji pou electroplate sifas composants kale, * * pwodwi yo p'ap undergo mold ou embroidery apre long-term itilization. Koman electroplating pwosesis inkluite screws, stamped pati, batteri cellules, machin pati, ti aksisyon an, ak so sou,

3. Surface polishing processing: Surface polishing processing is generally used for a long time in daily necessities. For example, if we produce a comb, which is a hardware component made by stamping, the edges and corners of the stamped comb are very sharp. We need to polish the sharp parts of the edges and corners to create a smooth face, so as not to cause harm to the human body during use.

active deyò san/sikilar sifas se de baz metòd de machining a deyò san/sikilar sifas nan pwosesis hardware, Et ekipman an ki te itilize se yon lathe. Nan jeneral fabrikè machinés, lathes kont pou apepwè 40% de la total kantite lajan machin. active se pwensipal metòd pou pale machin ak mwayèn presyon machin de diferan materyèl, osi osi a fin pwensipal machin metòd pou diferan materyèl ki pa suitable pou seri.

Lè pwodwi pati ki pa marye nan ti batches, active a deyò san sifas jeneralman pote sou yon lathe nòmal. Plizyè blad mwayèn otomatik latè ou latè otomatik yo ki te itilize nan pwodwi mas. Pli gwo disk pati ta dwe machin sou yon lathe vètikal. Moun gwo aks long bezwen pou yo machin sou yon lathe horizontal a grav.

Karakteristik de vire deyò sikilar sifas include: 1. Sèlman koupe ainaj, pwodwi konvenab, granj grinding ak enstale; 2. The cutting process is smooth and the fluctuation of cutting force is small, which is conducive to adopting high cutting speeds and improving productivity; 3. istwa machin a gen bon versatibilite Et ka pwosesis deyò sèk, fin figi, interne twou, seuil, ak chamfers nan yon sèl pwosesis qui. Konpayi pozisyon aksè ant sipèpoze fasil pou * * *; 4. Apache pou machin precision de ki pa-ferrous pati metal.

Bon!

[Servis s'ap]

1. Metal stamping proses, dezyèm, ak fabriksyon

2. Tablo metal pwodwi ak machin CNC

3. pwosesis ak pwodwisyon de pati metal nan plizyè industri

4. Pwosans de metal otomativ stamping Et vannen pati

5. Ak requirements kliyan, fè selon sa yo dessin ak echantiyon

6. Design ak pwodwisyon de plizyè molds

Emma Technology Co., Ltd. se youn nan pwofesyonèl ki te mennen pwofesyonèl sou pati précizisyon metal nan Chini, te etabli an 2006. Li principement empresyon biznis tankou CNC Machining pati, wòch metāl, ak wòch metāl pwogramasyon.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Spanish Basque

Spanish Basque