Tablo metāl proténsion, kòm non lan sije, se pwosesis ki itilize wòch metāl pou pwosesis tout bagay ki pi bezwen selon requirements. Matyè komen ki te itilize nan vi chak jou inklui kabinet konpitè, avek fòs, gazin automobil, gazin de lè conditioning kazings, entegre de fè gazings, gazing istasyon, etc. What are the processing techniques for Sheet Metal Processing? Chanjè a resumen sa a:

Process pwensipal de fil metal protéines include koupe Et koupe, CNC plough, punching Et shearing, en, rolling, riveting, en ak lòt metòd Et pwosesis. Li kapab tou di ke li se pwensip travay ak metod kontwòl de diferan devizyon. All sheet metal processing techniques are based on the need for sheet metal engineers to carefully design and label product drawings and specifications before operation. Pifò tèm nan teknoloji enkli: koupe, rive, bende, shearing, koupe, punching, déclenchement rive, retire soti, retire souf, pwan rive, koupe kwen, faisant, punching convex hull, punching lach, punching twou, déclenchement mesh twou, chamfering, returning dent, rale twou, tapping tooth, leveling, drilling, sinking twou, tapping plat, dans, spreaying, asanble, etc.

Nan ki sa wap objektif ki komen wòch la metal proténsion teknik? Kòm sa a:

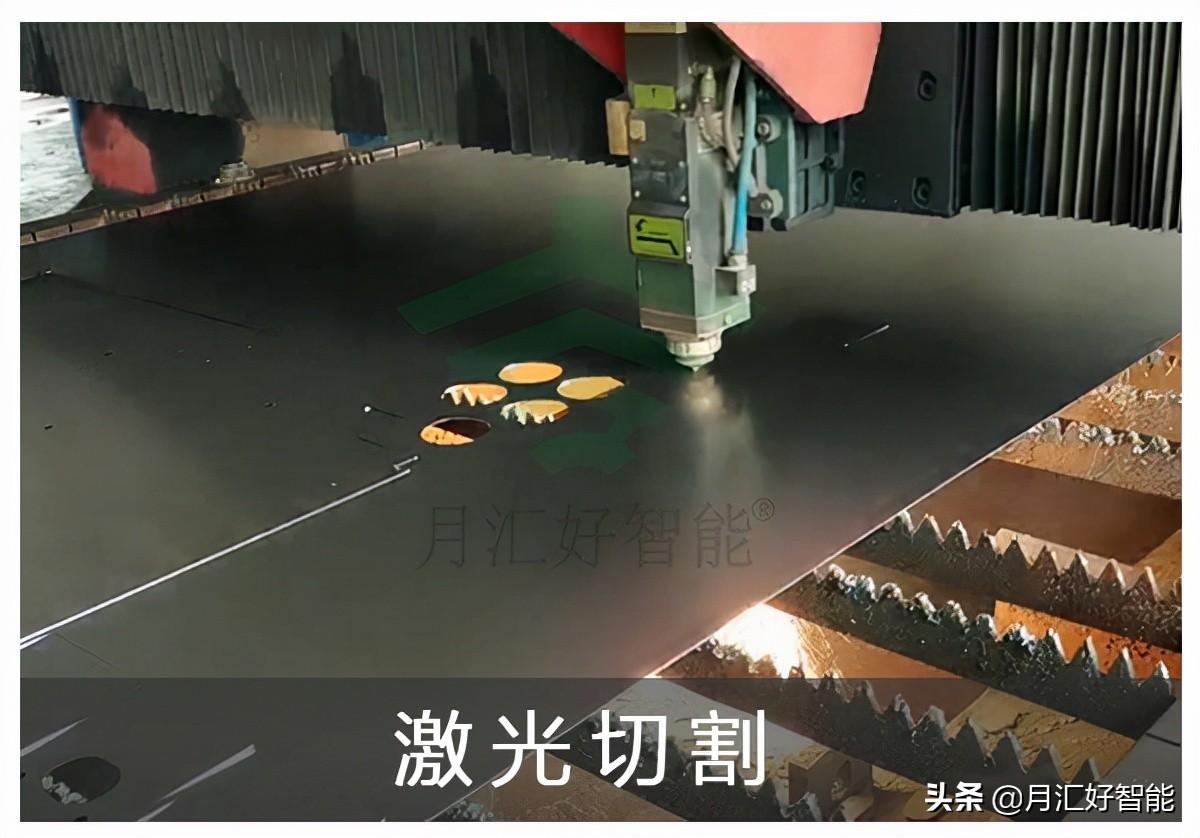

1. Cutting:

Gen diferan metòd koupe, ki vle di pwosesis de laser koupe, CNC punching, Et shearing de travay. NC nimerik kontwòl koupe Et laser koupe Coupe Coupe kapab itilize pou protéines byen pwès Et konplèks haute metral pati yo; machin shearing la ka koupe travay kote ak pi gwo dimansyon nan durée ak largè; Imaj ki tonbe nan fon pou pwosesis fòm Et san twou nan travay.

Lasè koupe de fil metal protéines

2. Dafiyman bò

Flanging, tou konnen tankou twou dessin an, se pou pwosesis ki itilize yon en sou yon nòmal kout ou lòt en pou fòme yon san twou rèd sou bò travay la. Li se pou fè yon gwo bouch espesifikye sou pre pwen bouch la, ki kapab fè bò dent yo punched sou peche travay a pi fò. li se jeneralman itilize sou travay pye ak yon pwès de mwens pase 1.5mm.

Olèt metòd protéines copper bar punching

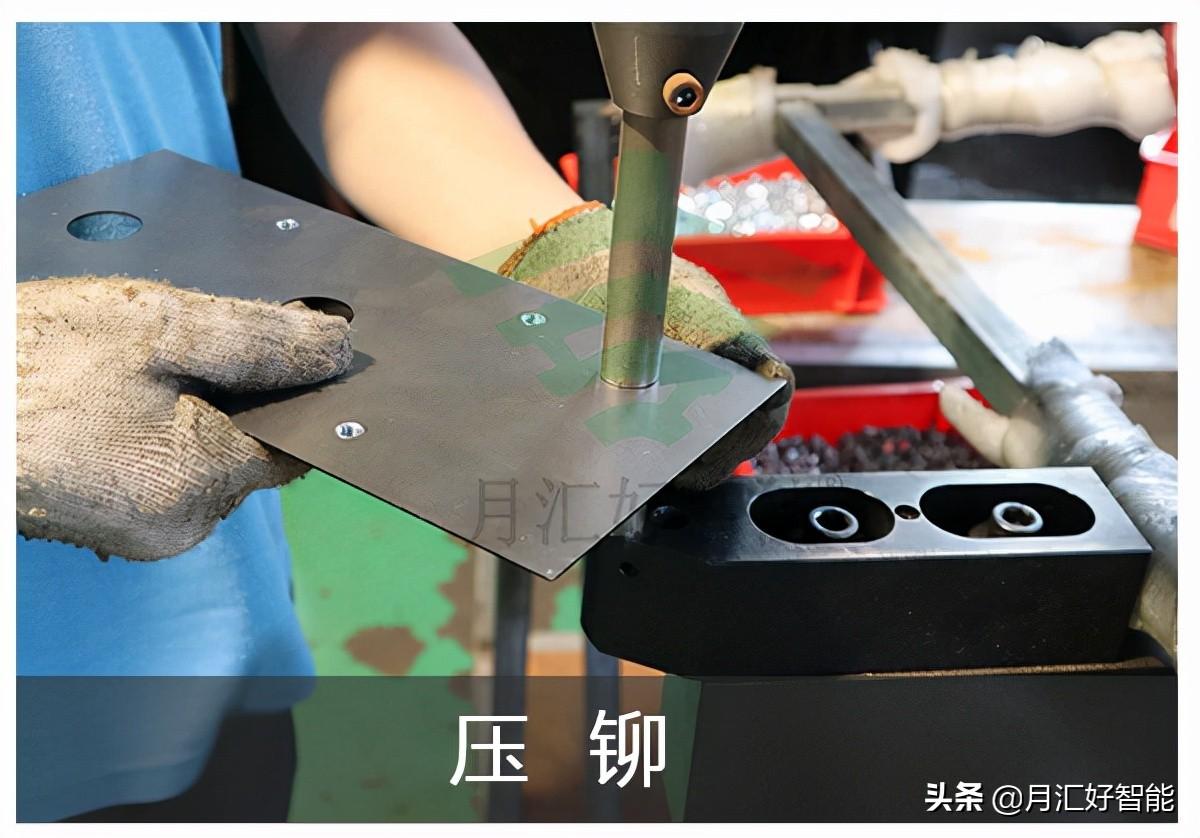

3. Riveting

Li jeneralman se pwosè a nan fòm rive Et pwe rive bouts, nuts, screws, etc. sou an travay ki itilize yon kout ou yon palèt hydraulic rive machin.

Sheet metal processing riveting

4. Ban

Bendi se yon pwosè nan ki yon kote yon kote travay ki fòme pa yon machin ki banye w ap itilize yon machin en ak ki gen rapò plon molds, ki kapab amelyore tout fòs de obrè a process é pou yon kèk mezi.

CNC ki deplase de fil metallèt protéines

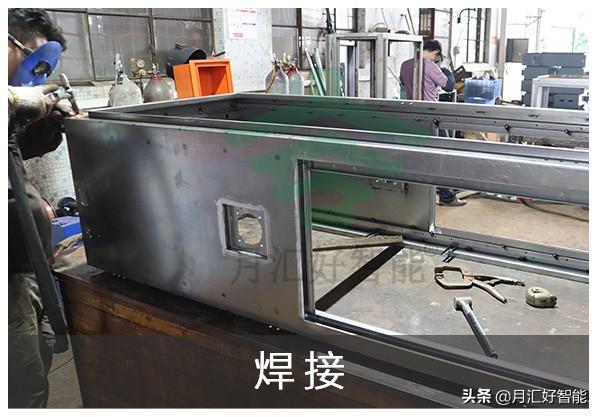

5. Enfòmase

The common types of welding processing include secondary protection welding, argon arc welding, electric welding, robot welding, and butt welding. The process mainly involves welding two or more parts together to achieve the purpose of processing finished products or assembled accessories; Alternativ, bò sèm endividyèl pati bezwen pou nou vannen pou sèvi prèske p'ap khume Et ogmante pa fòs.

Walleing de fil metal protéines bwat

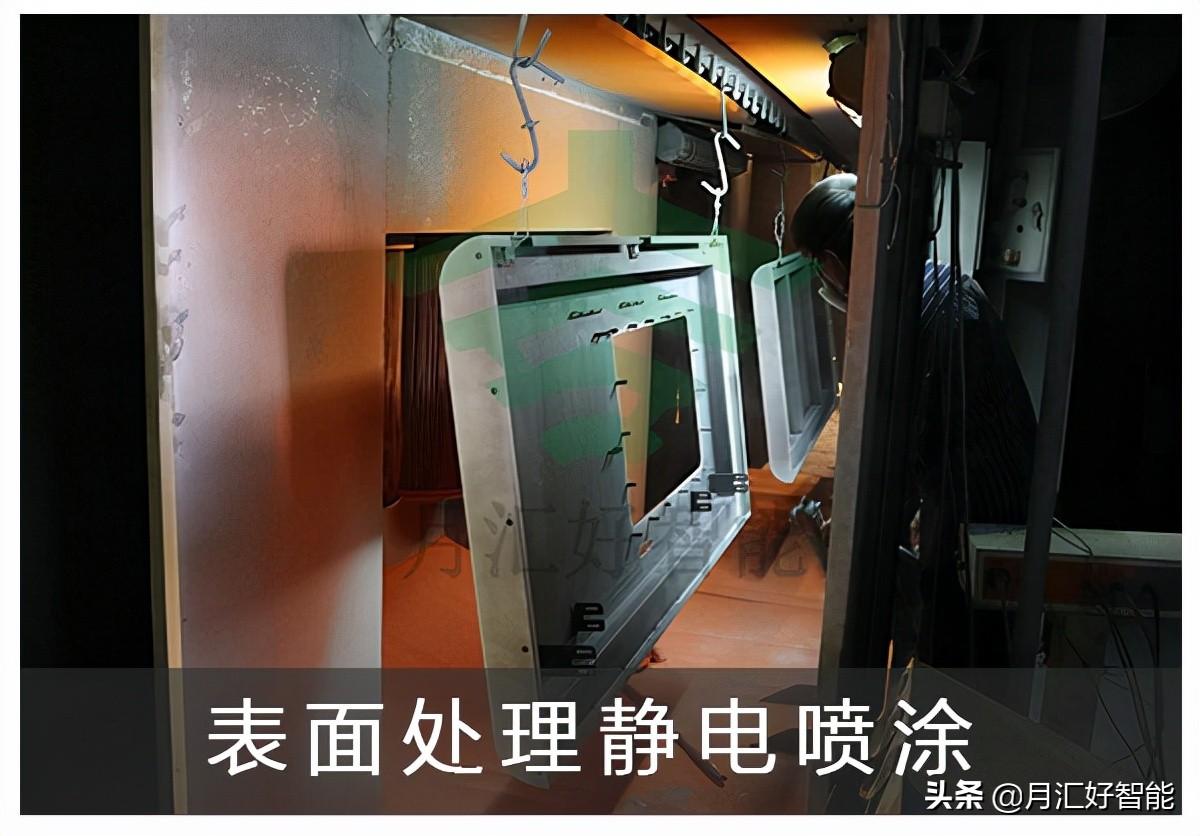

6. tretman sifas

Tretman sifas incluye phosphating kaple pèv en prève, electroplating de zinc, chromate, baking pent, oxidation, etc. Apre phosphating kapòt, obrèv la kapab electrostatically powder prève, suitable pou frèt-rowed Et galvanized plat; Elektroplating de zinc koulè jeneralman enplike sifas tretman de fil frèt ak pati machines; Chromate and oxidation are generally used for surface treatment of aluminum materials and aluminum profiles; Tretman sifas se pou fè pati wòch yo gade estetik plezi epi bay pwoteksyon pou yo tèt yo. Metòd tretman sifas tèt espesifikman an depende sou bezwen materyèl kliyan a

Olye metal proténsif kabinet pòt la s' ap fè

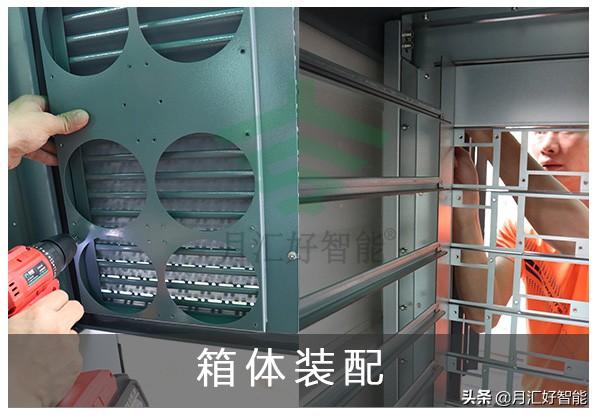

7. Asanble

Se asanble a de plizyè pati ou composants selon sa a nesesè de dessin an pou fòme yon pwodwi travay sou tout pwodwi. Pik travay ki monte a ka yon pwodwi ki fini ou yon pwodwi semi-fin.

Asanble de Charging pil bwat pou mete mwayèn protéines

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Spanish Basque

Spanish Basque