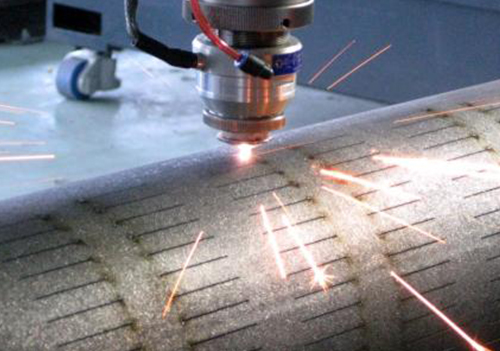

Reasons for jagged laser cutting

First, oscillation. If the laser cutting machine oscillates, then the product it cuts out will have serrations. It is divided into two reasons. One is the external condition of the machine, such as the machine in the process of cutting, such as the water tank, the fan will be too close, if too close, close to the machine, when it is running, it will oscillate the machine, and when the machine cuts the data, it will oscillate, which will affect the marginal effect of cutting.

Second, machine parallelism. If the machine parallelism is not properly installed, it will not be stable when the machine is running, so it will also vibrate during operation, and the cut product will also be produced by jagged teeth.

3. The lens is not locked. Sometimes, if the lens is not locked, the lens will also vibrate when the machine is running, and the light will also vibrate when the machine is cut, so the cut product will not work well, and there will be jagged teeth.

Fourth, the gear seat and other aspects. If the gear seat is close to its edge, causing slippage and other conditions, it has also caused this situation.

Fifth, the slider is worn. There is wear inside the slider or there are many things stuffed in the beads of the slider. It vibrates when running on the guide rail. So when cutting the data, there will be many serrations.

Six, the guide rails are not parallel. The two guide rail devices in the Y direction are not parallel. When it is running, it will get stuck, and when cutting, it will also have serrations. If the laser cutting machine has serrations when cutting, you can press the laser head with your hand to prevent it from vibrating when it is running. If you press it with your hand, it must be a slider problem. If there is still one, then you need to check the belt and gear. If there is a new machine, it must be that it is not properly installed when it is installed, or its control drive and motor are not paired.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque