In order to better cooperate with the tasks delivered by users and improve the company‘s production efficiency, Shenzhen EMAR Precision Technology has invested in the introduction of the Taiwan Group Series 4-axis CNC Machining center this month. The machine model of the Taiwan Group Series machining center purchased this time is V8565, which can realize the precision machining of 800 * 550 * 600mm parts. Let‘s take a look at the specific parameter values of this new equipment:

Equipment parameter name Unit parameter Other processing range Saddle stroke (Y axis) mm500 Table stroke (X axis) mm800 Spindle box stroke (Z axis) mm600 Spindle end face to table distance mm125~ 725 Table table Bearing KG500 Table size mm1000 * 500T grooves (number of grooves - slot width * spacing) mm5-18 * 100 Spindle speed range r/min50~ 12000 (direct connection) Motor power (rated/short time) kw7.5/11 Spindle diameter mm φ 150 Pull nail specification/P40T-I (MAS403) Shank specification/BT40 guide rail Z axis mm2-45 Roller Y axis mm2-45 Roller X axis mm2-35 Roller drive motor power X/Y/Zkw2.0 screw X/Y/Zmm4016/4016/4016 machine tool Accuracy Repeated positioning accuracy (X/Y/Z) mm0.007GB/T18400.4 Positioning accuracy (X/Y/Z) mm0.01GB/T18400.4 Speed Cutting feed speed range mm/min1-10000X, Y, Z axis fast moving speed mm/min48/48/48 Maximum diameter of the tool magazine (full knife/adjacent air knife) mm φ 75/φ 150 Tool weight kg7 Tool library capacity 24 Tool length mm250 Other configurations Total power supply capacity KVA25 numerical control system/Mitsubishi M80B Air source flow L/min280 (ANR) Air pressure MPa0.5~ 0.8 Cooling box volume L400 Host weight (approx.) kg5000 Machine tool appearance size (length * width * height) mm2460 * 3120 * 2320 Corresponds to X * Y * Z axis

Equipment parameter name Unit parameter Other processing range Saddle stroke (Y axis) mm500 Table stroke (X axis) mm800 Spindle box stroke (Z axis) mm600 Spindle end face to table distance mm125~ 725 Table table Bearing KG500 Table size mm1000 * 500T grooves (number of grooves - slot width * spacing) mm5-18 * 100 Spindle speed range r/min50~ 12000 (direct connection) Motor power (rated/short time) kw7.5/11 Spindle diameter mm φ 150 Pull nail specification/P40T-I (MAS403) Shank specification/BT40 guide rail Z axis mm2-45 Roller Y axis mm2-45 Roller X axis mm2-35 Roller drive motor power X/Y/Zkw2.0 screw X/Y/Zmm4016/4016/4016 machine tool Accuracy Repeated positioning accuracy (X/Y/Z) mm0.007GB/T18400.4 Positioning accuracy (X/Y/Z) mm0.01GB/T18400.4 Speed Cutting feed speed range mm/min1-10000X, Y, Z axis fast moving speed mm/min48/48/48 Maximum diameter of the tool magazine (full knife/adjacent air knife) mm φ 75/φ 150 Tool weight kg7 Tool library capacity 24 Tool length mm250 Other configurations Total power supply capacity KVA25 numerical control system/Mitsubishi M80B Air source flow L/min280 (ANR) Air pressure MPa0.5~ 0.8 Cooling box volume L400 Host weight (approx.) kg5000 Machine tool appearance size (length * width * height) mm2460 * 3120 * 2320 Corresponds to X * Y * Z axis

The main processing features of the newly added series of machining centers are as follows: 1. The whole machine is fully enclosed and protected, and the equipment is beautiful in appearance. It is very convenient to use and maintain in the later stage. 2. The structure of the whole machine is column type. It adopts the structure of a cross sliding table, ranking among the super-large stable base and high-rigidity large-span herringbone columns, which will not vibrate and deform during high-speed cutting. 3. The guide rail is carried by ball line rails, with high rigidity, low friction and low noise. 4. The basic components are cast with high-quality resin sand molding and high-strength cast iron materials, which greatly guarantees the rigidity, stability and accuracy of the machine tool. 5. Large-diameter C3-grade lead screw with pre-drawing mechanism Eliminating part of the thermal extension, the screw bearing adopts automatic lubrication, prolonging the service life of the bearing; 6. The spindle adopts a high-speed spindle unit, equipped with BT40-12000r/min direct coupling, and the front end of the spindle adopts a labyrinth design and has an air curtain protection function to prevent the cutting fluid from entering the spindle bearing; 7. The tool magazine adopts 24 knife arm type tool magazines, which have significant quality and stability; 8. The chip removal of the machine tool is standard equipped with both sides of the slope and after flushing. The water tank adopts a rear design and a double-layer water tank filter system structure, providing a good cutting fluid system for the processing of parts; 9. Equipped with a volumetric and forced lubricating oil system to ensure good lubrication effect of each moving part of the machine tool; 10. Equipped with high-performance Mitsubishi M80B numerical control system ensures the stability of machine tool control and the functions and auxiliary features of numerical control processing;

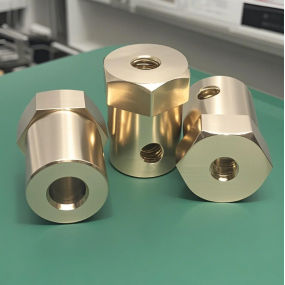

The newly added machining center series mainly targets the product field including precision parts, aviation parts, drone parts, medical parts and communication parts customization and mass production. Up to now, the company is equipped with more than 100 numerical control equipment. If you have relevant precision parts processing needs, you are welcome to call EMAR. We will provide you with perfect product solutions and high-quality services.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque