How does numerical control machine work? How does CNC process molds?

The numerical control machine tool is generally composed of the machine tool body, the numerical control system (CNC system is the core of the numerical control machine tool and is a special computer), the driving device and the auxiliary device. The basic functions of the numerical control system include input function, interpolation function and servo control. Its working process is: after receiving the numerical control program through the input function, it combines the data such as tool setting parameters, control parameters and compensation parameters set by the operator on the panel to decode, and perform logic operations, which are converted into a series of logical electrical signals, thereby sending out corresponding command pulses to control the driving device of the machine tool, so that the machine tool axes move, and the machine tool is operated to achieve the expected machining function.

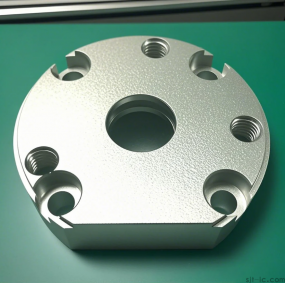

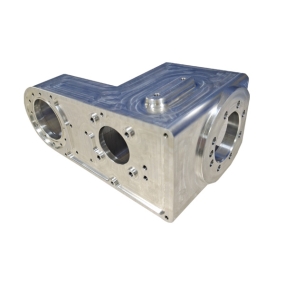

After the mold designer designs a 3D mold (also called a parting mold) according to the customer‘s product drawing, he needs to perform numerical control programming on the mold drawing file. After determining the size of the machining tool and the way of cutting the tool, the numerical control program can be compiled with UG. This numerical control program is a text file, which contains the code that the machine can recognize. After the machine operator receives the program sheet and the numerical control program, he must install the workpiece on the numerical control machine table as required, install the tool on the spindle, set the tool setting parameters in the machine panel, and modify the individual instructions according to the specific conditions of the machine. After the numerical control program is transmitted to the machine tool through the network DNC. The tools on the machine tool perform cutting movements under the control of these numerical control instructions, and other cooling systems work synchronously. One program after another is executed, so that the mold is machined.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque