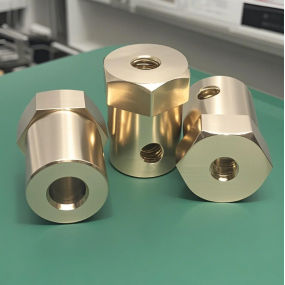

Shenzhen EMAR Precision Technology Co., Ltd. is a professional manufacturer dedicated to high-precision cnc external processing. It includes optical, automotive, office automation and aviation parts. The company has more than 100 numerical control centering machines, numerical control cutting machines, and CNC Machining centers. With advanced projectors, three-coordinate detectors, spectrometers and other precision testing instruments. Today EMAR Precision Technology will share with you what are the requirements for industrial aluminum profiles in aviation parts processing?

With the rapid development of the aviation industry, the industrial aluminum profile work in progress has put forward higher and higher requirements, especially high-speed military and civil aircraft require the use of the most perfect work in progress, so that the structure of each component is more reasonable, to ensure the structural quality of the lightest, the largest strength and rigidity, while greatly reducing the number of components, reduce the group of paddles, joint and maintenance costs, to ensure a perfect and beautiful surface (good sealing, no seams, no deformation, etc.).

A: Since industrial aluminum profiles are used as structural parts in key parts of aircraft, they are required to have good comprehensive properties and uniform organization, especially for finished products. The defects of coarse crystal rings in extruded quenched products are difficult to avoid, and it is also one of the research topics that extrusion workers around the world have been working on for decades with little success.

A: Since industrial aluminum profiles are used as structural parts in key parts of aircraft, they are required to have good comprehensive properties and uniform organization, especially for finished products. The defects of coarse crystal rings in extruded quenched products are difficult to avoid, and it is also one of the research topics that extrusion workers around the world have been working on for decades with little success.

B: Large industrial aluminum profiles are particularly important structural parts on aircraft, and profiles are required to have excellent mechanical properties. Therefore, aluminum profiles must be extruded with hard aluminum or super hard aluminum alloys.

C: For aluminum profiles such as cruciferous girders and comb-shaped joints, on the one hand, the large cross-sectional area often makes the extrusion deformation coefficient relatively small, and on the other hand, its transverse and high-direction must bear a large load, so it is required that its transverse and high-direction have high mechanical properties. This contradiction is often an important reason for the scrapping of aluminum profiles.

EMAR Precision Technology was established in 2001, the company took the lead in passing ISO9001, ISO14001, IATF16949 and other quality management certifications, is a rare high-paying technology enterprise with auto parts processing qualifications in Shenzhen, the company has a first-class technical R & D team and technical personnel, in precision parts processing has long experience, our company‘s numerical control centering machine and turn-milling composite machining center in aviation parts processing has excellent advantages, with a one-time clamping to complete most or all of the process of fabrication.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque