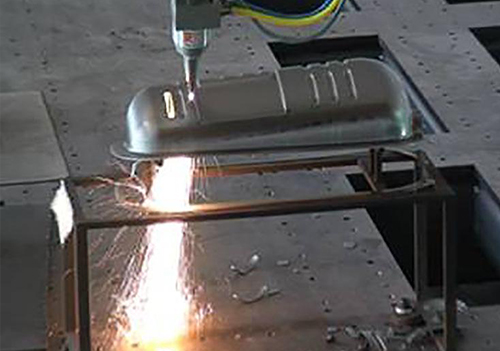

What materials can be cut by laser cutting?

Stainless steel, stainless steel is used a lot in various industries. When cutting stainless steel, the fiber laser cutting machine uses nitrogen to obtain a non-oxidized and burr-free edge without affecting the edge oxidation. Coating the oil film on the surface of the sheet will get better perforation effect without reducing the processing quality.

Aluminum, although aluminum has high reflectivity and thermal conductivity for fiber laser cutting machines, it depends on the type of alloy and laser capability. When cut with oxygen, the cut surface is rough and hard. When cut with nitrogen, the cut surface is smooth. Pure aluminum is very difficult to cut because of its high purity. It can only be cut when the equipment on the fiber laser cutting machine system has a "reflection absorption" device. Otherwise, the reflection will destroy the optical components.

Titanium and titanium sheets are cut with argon and nitrogen as processing gases. Other parameters can refer to nickel-chromium steel.

When laser processing cuts stainless steel and aluminum-zinc plates, the workpiece has burrs. First of all, it depends on the burrs when cutting stainless steel, and it is possible to check whether the nozzle needs to be replaced and whether the guide rail movement is unstable. But it does not rule out the reason for the cutting speed. The cutting speed sometimes leads to the situation that the plate cannot be cut through, which is particularly prominent when processing aluminum-zinc plates.

Cutting and machining small holes shows deformation because the machine does not use the method of blasting perforation when machining small holes, but uses the method of pulse perforation.

This causes the laser energy to concentrate too much in a small area, causing the non-processed area to be burned, causing the deformation of the hole and affecting the processing quality.

At this time, the pulse perforation method should be changed to the blasting perforation method in the processing program to solve the problem. On the other hand, the laser cutting machine with lower power is just the opposite. In the small hole processing, the pulse perforation method should be used to achieve better surface finish.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque