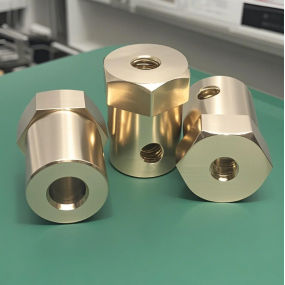

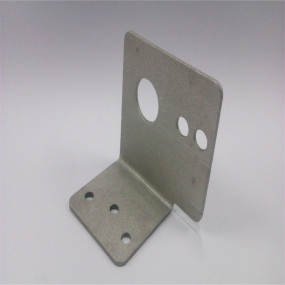

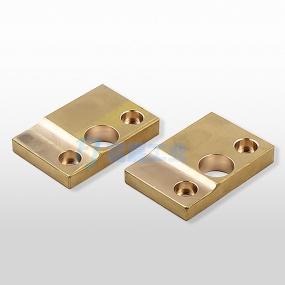

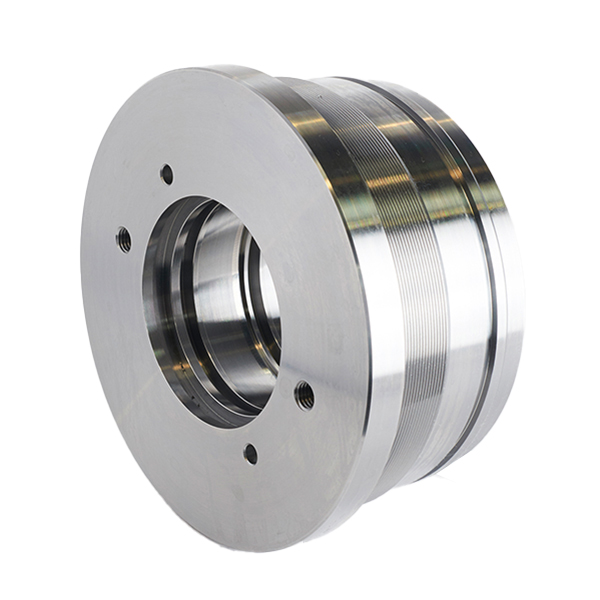

Aluminum alloy CNC Machining is a method of machining aluminum alloy materials using CNC machine tools. Aluminum alloy has the advantages of low density, high strength, good machinability, corrosion resistance, etc., so it is widely used in aviation, aerospace, automotive, electronics, machinery manufacturing and other fields. Aluminum alloy CNC machining has the advantages of high machining accuracy, high machining efficiency, and low machining cost. It can meet the manufacturing needs of products with various complex shapes and high precision requirements.  In the aluminum alloy cnc machining process, the following points need to be paid attention to: The choice of cutting fluid, cutting fluid can reduce the friction between the tool and the workpiece, reduce the cutting force and cutting temperature, reduce the wear of the tool, and improve the surface quality of the workpiece. Selection of tool materials, according to the characteristics of aluminum alloy, select the appropriate tool materials, such as high-speed steel, cemented carbide, etc. Selection of tool geometric parameters, rationally set the geometric parameters such as the front angle, back angle, main declination angle of the tool, in order to improve the cutting performance and durability of the tool. Selection of cutting dosage, according to the characteristics of aluminum alloy and processing requirements, rationally set the cutting speed, feed and cutting depth and other cutting dosage. Monitoring of the machining process, pay close attention to the cutting force, cutting temperature, tool wear and other conditions during the machining process, and adjust the cutting parameters and tools in a timely manner. Inspection after machining, check the dimensional accuracy and surface quality of the machined workpiece, and rework or scrap in time if there are unqualified products. Operator training and management, professional skills training and safety education for operators to improve their operating skills and safety awareness. Equipment maintenance and maintenance, regular maintenance and maintenance of CNC machine tools to keep equipment in good condition and prolong its service life.

In the aluminum alloy cnc machining process, the following points need to be paid attention to: The choice of cutting fluid, cutting fluid can reduce the friction between the tool and the workpiece, reduce the cutting force and cutting temperature, reduce the wear of the tool, and improve the surface quality of the workpiece. Selection of tool materials, according to the characteristics of aluminum alloy, select the appropriate tool materials, such as high-speed steel, cemented carbide, etc. Selection of tool geometric parameters, rationally set the geometric parameters such as the front angle, back angle, main declination angle of the tool, in order to improve the cutting performance and durability of the tool. Selection of cutting dosage, according to the characteristics of aluminum alloy and processing requirements, rationally set the cutting speed, feed and cutting depth and other cutting dosage. Monitoring of the machining process, pay close attention to the cutting force, cutting temperature, tool wear and other conditions during the machining process, and adjust the cutting parameters and tools in a timely manner. Inspection after machining, check the dimensional accuracy and surface quality of the machined workpiece, and rework or scrap in time if there are unqualified products. Operator training and management, professional skills training and safety education for operators to improve their operating skills and safety awareness. Equipment maintenance and maintenance, regular maintenance and maintenance of CNC machine tools to keep equipment in good condition and prolong its service life.

안녕하세요!EMAR 회사 웹 사이트에 오신 것을 환영합니다!

Korean

Korean » »

» »

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque