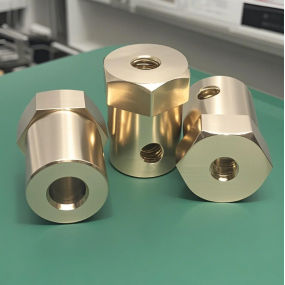

CNC numerical control machining, that is, computer digital control machining, is a way of high-precision machining by computer program control of machine tools. It uses computer programming, and by controlling the movement and cutting process of machine tools, parts with complex shapes and high-precision requirements can be machined. The characteristics of CNC numerical control machining include:  1, High machining accuracy: Due to the control of computer programs, CNC numerical control machining can achieve extremely high machining accuracy, and even achieve micron-level accuracy. 2, High machining efficiency: CNC numerical control machining can complete the processing of complex parts in a short time, improving production efficiency. 3. Good processing quality: Due to the precise control of cutting force, cutting speed and cutting depth, CNC numerical control machining can obtain high-quality machining surface. 4. Wide processing range: CNC numerical control machining can process various materials, including metal, plastic, wood, etc., and can process various complex shapes. 5. High degree of automation: CNC numerical control machining can reduce manual intervention and realize automated production. 6. Strong programmability: CNC numerical control machining can change the processing process by modifying the computer program, with strong programmability.

1, High machining accuracy: Due to the control of computer programs, CNC numerical control machining can achieve extremely high machining accuracy, and even achieve micron-level accuracy. 2, High machining efficiency: CNC numerical control machining can complete the processing of complex parts in a short time, improving production efficiency. 3. Good processing quality: Due to the precise control of cutting force, cutting speed and cutting depth, CNC numerical control machining can obtain high-quality machining surface. 4. Wide processing range: CNC numerical control machining can process various materials, including metal, plastic, wood, etc., and can process various complex shapes. 5. High degree of automation: CNC numerical control machining can reduce manual intervention and realize automated production. 6. Strong programmability: CNC numerical control machining can change the processing process by modifying the computer program, with strong programmability.

안녕하세요!EMAR 회사 웹 사이트에 오신 것을 환영합니다!

Korean

Korean » »

» »

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque