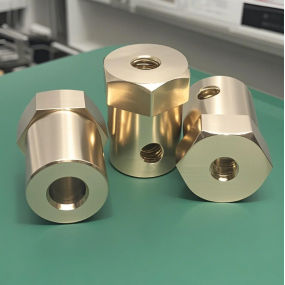

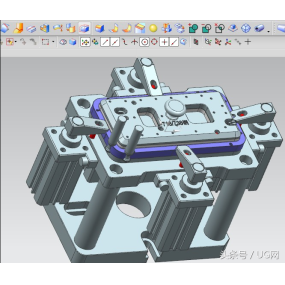

The size of the public service of the precision hardware bending parts is related to the scale and the selected public service grade. The selection of public service grade should not only meet the planning requirements, but also consider the possibility and economy of the process. That is to say, if you meet the application requirements, try to increase the public service value, that is, choose a lower public service grade.

"GB/T13914-2002 Standard Service for Bending Parts" stipulates the standard service for bending parts. The standard service is stipulated according to the flat bending parts and the forming bending parts respectively. The standard service value of the bending parts is related to the two scales of the bending parts and the plate thickness, on the other hand, it is related to the accuracy grade.  service is the range of scale change. The higher its value, the lower the accuracy and the less difficult it is to process. The smaller the value, the higher the accuracy and the more difficult it is to process. So, which are the most items to pay attention to in production?

service is the range of scale change. The higher its value, the lower the accuracy and the less difficult it is to process. The smaller the value, the higher the accuracy and the more difficult it is to process. So, which are the most items to pay attention to in production?

1. Bending viewpoint: the viewpoint scale of the bent part formed by bending;

2. Punching viewpoint: the viewpoint scale formed by punching at the plane of the flat plate or formed part;

3. Punching fillet radius: the linear scale of the fillet radius of the bent part processed by punching, blanking and other separate processes;

4. Forming scale: the linear scale of a bent part formed by bending, stretching, and other processes.

5. Blanking scale: the linear scale of the bent parts processed by punching, blanking, and other separate processes.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click: www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque