Laser cutting should also be protected

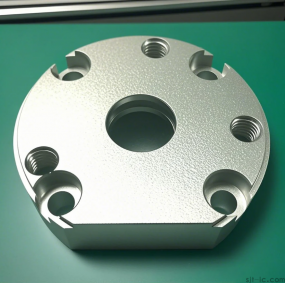

The purpose of laser cutting annealing is to eliminate the defects of arrangement, improve the arrangement to homogenize the composition and refine the grain, improve the mechanical properties of steel, and reduce the residual stress. At the same time, it can reduce the hardness, improve the plasticity and toughness of the machine tool, and improve the machining performance.

Annealing is not only to eliminate and improve the arrangement shortcomings and internal stress left by the previous process, but also to prepare for the subsequent process. The workpiece is irradiated with a concentrated high-power density laser beam to carry out the process of operation. Therefore, when the operator operates, it is necessary to do a good job of protection, otherwise the stronger beam of light will damage the skin and eyes.

The workshop space should be wide, because there are some workpieces stacked in the workshop, and their appearance and length vary. During the processing process, the operator‘s operation needs to have enough space. Therefore, the workshop space should be wide. Sound insulation is good, and laser cutting processing generally produces a lot of noise. In order to prevent disturbing the people, laser cutting processing plants are generally built in places far from residential areas. Of course, it is still necessary to do a good job of relevant sound insulation treatment.

Adopting the necessary heat treatment processing is of great assistance to the later application. Considering that the cutting machine is the main purpose of the material processing equipment, we can extend the service life of the equipment by improving some physical properties of the metal laser cutting machine body. Therefore, the annealing process of laser cutting processing is a very important step.

To wear a good laser protective goggles, the principle of protective goggles can be divided into reflection, absorption, diffraction, and composite types, etc. They will be filtered and protected according to the laser radiation wavelength of the laser cutting machine to achieve the maintenance of the laser cutting machine on the human body. This is the safer and more convenient laser cutting machine protective equipment on the market.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque